4×8 Hardie board, a ubiquitous presence in construction, offers a robust and versatile solution for exterior cladding. This guide delves into the multifaceted world of Hardie board, exploring its various types, installation techniques, applications, maintenance, and environmental impact. From understanding the differences between siding and trim to mastering proper fastening methods and calculating material costs, we provide a complete resource for homeowners, contractors, and anyone interested in this durable building material.

We’ll examine the physical characteristics of standard 4×8 Hardie board panels, comparing weight, thickness, and price across different product lines. This detailed analysis will empower you to make informed decisions when selecting the ideal Hardie board for your specific project needs, whether it’s a residential renovation or a large-scale commercial undertaking. We’ll also cover the crucial aspects of installation, maintenance, and the environmental considerations associated with this popular building material.

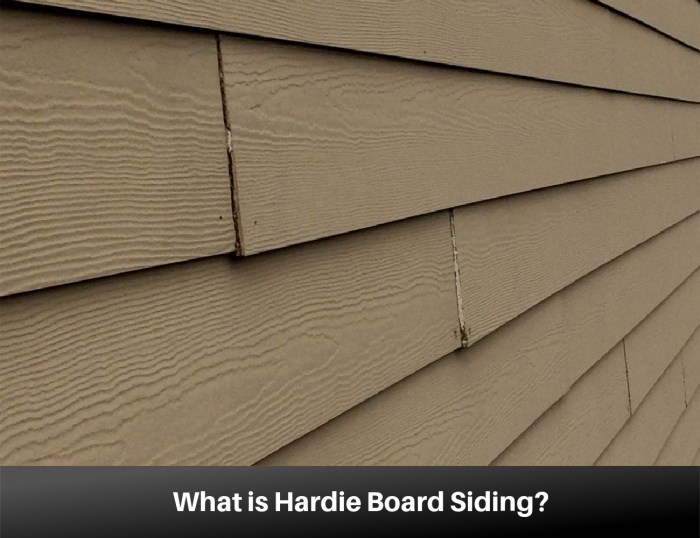

Product Overview: 4×8 Hardie Board

James Hardie fiber cement products, specifically their 4×8 sheets, are a popular choice for exterior cladding due to their durability and versatility. These large-format panels offer significant advantages in terms of installation speed and reduced labor costs compared to smaller materials. Understanding the different types and characteristics of 4×8 Hardie boards is crucial for selecting the right product for any given project.

Physical Characteristics of Standard 4×8 Hardie Board

Standard 4×8 Hardie boards typically measure 4 feet by 8 feet (48 inches x 96 inches), though slight variations may occur due to manufacturing tolerances. They are composed of a cement composite reinforced with cellulose fibers, providing exceptional strength and resistance to impact, moisture, and insects. The surface texture varies depending on the specific product line, ranging from smooth to textured finishes designed to mimic wood grain or other materials. The boards are typically delivered in bundles, and their weight varies considerably depending on the type and thickness.

Types of 4×8 Hardie Board

James Hardie offers a range of 4×8 fiber cement boards designed for different applications. The most common types include siding, trim, and soffit panels. HardiePlank® siding is designed for large exterior wall applications and comes in various profiles and textures to replicate the look of wood lap siding, vertical siding, or shingles. HardieTrim® boards, typically thicker and more robust, are used for window and door trim, fascia, and other exterior architectural details. HardieSoffit® panels are designed for under-eave soffit applications, offering durability and resistance to moisture damage. Each type is engineered for its specific purpose, impacting its thickness, weight, and price.

Weight and Thickness Variations

The weight and thickness of 4×8 Hardie boards vary considerably depending on the product type and intended application. For example, HardiePlank siding is generally lighter and thinner than HardieTrim boards, which are designed to withstand more stress and impact. Thicker boards generally weigh more and provide greater durability and rigidity. Precise weight specifications can be found in the manufacturer’s technical data sheets, but generally, expect significant differences between the various product lines. A typical HardiePlank siding panel might weigh around 40-50 pounds, while a HardieTrim board could weigh considerably more, potentially exceeding 70 pounds.

Price Comparison of 4×8 Hardie Board Options

Pricing for 4×8 Hardie boards varies based on the type, finish, and retailer. Prices are also subject to change due to market fluctuations. The table below offers a general comparison of price points. These are approximate prices and should be verified with local suppliers.

| Product Type | Thickness (in) | Approximate Price (USD) | Notes |

|---|---|---|---|

| HardiePlank Lap Siding | 0.5 | $30 – $45 | Price varies by profile and color |

| HardiePlank Vertical Siding | 0.5 | $35 – $50 | Price varies by profile and color |

| HardieTrim Boards | 0.75 | $40 – $60 | Price varies by profile |

| HardieSoffit Panels | 0.5 | $25 – $40 | Price varies by color and panel type |

Installation Methods

Installing 4×8 Hardie board siding requires careful planning and execution to ensure a durable and aesthetically pleasing finish. Proper preparation and adherence to best practices are crucial for a successful installation. This section details the necessary tools, safety precautions, surface preparation, installation steps, cutting techniques, and fastening methods.

Necessary Tools and Safety Equipment, 4×8 hardie board

Safe and efficient installation of Hardie board necessitates the use of appropriate tools and safety equipment. Failure to do so can lead to injury or damage to the material.

- Measuring tape and level: Accurate measurements are essential for proper spacing and alignment.

- Circular saw with a fine-tooth blade specifically designed for cutting fiber cement: This ensures clean cuts and prevents chipping.

- Safety glasses: Protecting your eyes from flying debris is paramount.

- Hearing protection: The noise generated during cutting and fastening can be significant.

- Work gloves: Protecting your hands from splinters and abrasions is crucial.

- Nail gun (recommended): A pneumatic nail gun significantly speeds up the installation process, ensuring consistent fastener depth.

- Hammer (alternative to nail gun): A claw hammer can be used, but requires more time and effort.

- Caulk gun and exterior-grade caulk: For sealing gaps and joints.

- Putty knife: For applying and smoothing caulk.

- Ladder or scaffolding: To reach higher areas safely.

Surface Preparation for Hardie Board Installation

Thorough surface preparation is critical for ensuring a secure and long-lasting installation. Any imperfections or irregularities in the underlying structure will affect the final appearance and longevity of the siding.

- Inspect the existing wall sheathing for damage or rot. Repair any damaged areas before proceeding.

- Ensure the sheathing is properly fastened and level. Uneven sheathing will lead to uneven siding.

- Clean the surface of any dirt, debris, or loose material. A pressure washer can be helpful for this task.

- Apply a water-resistant barrier, such as house wrap, to protect the sheathing from moisture.

- Install any necessary flashing around windows, doors, and other openings to prevent water penetration.

Step-by-Step Guide for Installing 4×8 Hardie Board Siding

Following these steps ensures a proper installation, maximizing the lifespan and aesthetic appeal of your Hardie board siding.

- Start at a corner or a prominent vertical line, ensuring the first piece is perfectly plumb and level. Use a level and shims as needed.

- Fasten the first piece of Hardie board using appropriate fasteners, spaced according to manufacturer’s recommendations. Avoid overdriving fasteners.

- Install subsequent pieces, overlapping the edges and maintaining consistent spacing. Use a level to ensure alignment.

- Caulk all joints and seams to prevent water penetration. Use a high-quality, exterior-grade caulk.

- Install trim pieces around windows, doors, and other openings.

- Inspect the completed installation to ensure proper alignment and fastening.

Cutting and Trimming 4×8 Hardie Board

Precise cutting is crucial for a professional finish. Using the correct tools and techniques minimizes chipping and ensures accurate fits.

When cutting Hardie board, use a circular saw with a fine-tooth blade designed for fiber cement. Score the board lightly with a utility knife before cutting to prevent chipping. Always wear safety glasses and hearing protection.

Proper Fastening Techniques

Appropriate fastening is essential for a secure and long-lasting installation. Incorrect fastening can lead to damage and premature failure of the siding.

The following visual guide demonstrates proper fastening techniques. Remember to always consult the manufacturer’s instructions for specific recommendations.

- Visual Guide: Imagine a diagram showing a section of Hardie board. Fasteners should be driven straight, avoiding angled or off-center placement. They should be spaced evenly according to manufacturer specifications, typically every 6-8 inches. The fasteners should be driven just below the surface of the board to avoid damaging the surface. Overdriving fasteners should be avoided, as it can cause cracking.

Applications and Uses

Hardie board, with its durability and versatility, finds extensive use in a wide range of residential and commercial construction projects. Its resistance to moisture, insects, and fire makes it a superior choice for exterior cladding, offering long-term protection and aesthetic appeal. This section details the diverse applications of 4×8 Hardie board, highlighting its advantages over alternative materials and showcasing its adaptability to various architectural styles.

Residential Applications of 4×8 Hardie Board

Hardie board’s popularity in residential construction stems from its ability to withstand harsh weather conditions and its ease of installation. The following are five common applications in homes:

- Siding: 4×8 Hardie board is a prevalent choice for house siding, providing a durable and attractive exterior finish. Its various textures and colors allow for customization to match different architectural styles.

- Soffits and Fascia: Its resistance to moisture and rot makes it ideal for soffits and fascia boards, protecting the vulnerable areas under the eaves.

- Shutters and Trim: Hardie board shutters and trim offer a low-maintenance, long-lasting alternative to wood, enhancing the overall aesthetic appeal of the home.

- Garage Doors: Hardie board can be used to clad garage doors, providing a durable and aesthetically pleasing finish that resists dents and damage.

- Exterior Walls of Sheds and Outbuildings: The material’s durability and weather resistance make it suitable for constructing and cladding smaller structures like sheds and outbuildings.

Commercial Applications of 4×8 Hardie Board

The robust nature and aesthetic versatility of Hardie board extend its use beyond residential projects. Its application in commercial buildings reflects its ability to meet demanding structural and design requirements.

Hardie board is frequently employed in commercial buildings for applications such as cladding for office buildings, retail spaces, and industrial facilities. Its fire-resistant properties are particularly valuable in high-traffic areas. The ability to customize the appearance of Hardie board allows for seamless integration into diverse commercial building designs, from modern glass structures to traditional brick buildings. Large-scale projects often benefit from the speed and efficiency of Hardie board installation, minimizing disruption and accelerating project completion.

Advantages of Hardie Board Over Alternative Cladding Materials

Compared to other cladding materials, Hardie board offers several key advantages.

Unlike wood, Hardie board is resistant to rot, insect infestation, and fire, requiring minimal maintenance. It also outperforms vinyl siding in terms of durability and resistance to impact damage. Its superior longevity translates to lower long-term costs compared to materials that require frequent replacement or repairs. The wide range of colors and textures available with Hardie board provides greater design flexibility than many alternative options. Furthermore, Hardie board’s non-combustible nature enhances fire safety in residential and commercial applications.

Aesthetic Appeal of Hardie Board in Different Architectural Styles

Hardie board’s adaptability allows it to complement various architectural styles.

Its versatility in texture and color enables it to seamlessly integrate into both traditional and modern designs. For instance, a smooth, painted finish might suit a contemporary home, while a textured, wood-grain finish could complement a more traditional design. The ability to customize the appearance of Hardie board ensures it can enhance the aesthetic appeal of various architectural styles without compromising on durability and performance.

Examples of Hardie Board Usage in Various Exterior Designs

The following examples illustrate the diverse applications of Hardie board in different exterior designs:

- Craftsman Style: A home featuring Hardie board siding with a deep, rich color and wood-grain texture, accented by detailed trim work, embodies the warmth and craftsmanship of this style.

- Modern Farmhouse: A clean, white Hardie board exterior with simple lines and dark window frames creates a striking contrast, reflecting the minimalist aesthetic of this style.

- Victorian Style: Intricate detailing and a variety of colors and textures in Hardie board siding, combined with decorative trim, can capture the ornate elegance of Victorian architecture.

Maintenance and Durability

Hardie board siding, known for its robust composition and resistance to the elements, offers a significant advantage in terms of longevity and low-maintenance upkeep compared to traditional wood siding. Understanding the proper maintenance procedures and the impact of environmental factors ensures the extended lifespan and aesthetic appeal of your Hardie board investment. This section details the expected lifespan, maintenance recommendations, and the effects of various factors on Hardie board’s performance.

Properly installed and maintained 4×8 Hardie board siding boasts a remarkable lifespan. While the manufacturer’s warranty may specify a certain period, real-world experience shows that with regular care, Hardie board can easily last 30 years or more, sometimes even exceeding 50 years depending on climate and maintenance practices. This superior durability is attributed to its cement composition, making it highly resistant to rot, insect infestation, and fire.

Expected Lifespan of Hardie Board

The lifespan of Hardie board siding is significantly influenced by several factors. These include the quality of installation, the frequency and thoroughness of maintenance, and the prevailing environmental conditions. A professionally installed system in a moderate climate with regular maintenance can readily surpass the manufacturer’s warranty, often lasting well beyond 30 years. Conversely, neglecting maintenance in harsh climates might shorten the lifespan. However, even with minimal maintenance, Hardie board significantly outperforms wood siding in terms of longevity. For example, a home in a coastal region with frequent exposure to salt spray and strong winds might require more frequent cleaning and repainting, but the underlying Hardie board will still maintain structural integrity for many decades, far exceeding the lifespan of wood siding under the same conditions.

Recommended Maintenance Procedures

Regular cleaning and inspection are crucial for maintaining the appearance and structural integrity of Hardie board. Annual inspections should check for any damage, such as cracks, loose fasteners, or signs of moisture penetration. Cleaning should be done at least once a year, using a pressure washer set to a low pressure setting (avoiding high pressure which can damage the surface) and a mild detergent solution. A soft-bristled brush can be used to scrub away stubborn dirt or mildew. Promptly addressing any minor damage prevents further deterioration. Regular repainting, following the manufacturer’s guidelines for appropriate primer and paint types, is also essential to protect the siding from the elements and maintain its aesthetic appeal.

Cleaning and Repairing Minor Damage

Minor scratches or surface damage can often be repaired with a touch-up paint. For more significant damage, such as cracks or dents, professional repair may be necessary. The repair process typically involves filling the damaged area with a suitable patching compound, allowing it to dry completely, and then sanding smooth before applying primer and paint. Always use paints specifically designed for Hardie board to ensure proper adhesion and long-term protection. For larger areas of damage, it might be more cost-effective to replace the affected sections of siding. This is particularly true for areas subjected to extreme weather conditions or significant impact damage.

Effects of Weather Conditions on Hardie Board

Hardie board’s performance is affected by various weather conditions. Extreme temperature fluctuations can cause expansion and contraction, potentially leading to minor cracking if not properly maintained. Prolonged exposure to moisture, particularly in poorly ventilated areas, can promote the growth of mildew or algae. High winds and hail can cause impact damage. Coastal areas with high salinity can accelerate the degradation of paint finishes. Regular maintenance, including cleaning and repainting, mitigates these effects and extends the siding’s lifespan. For instance, in coastal areas, using a high-quality marine-grade paint will significantly enhance the protection against salt spray.

Impact of Different Paint Types on Hardie Board Longevity

The choice of paint significantly impacts the longevity of Hardie board. Using a high-quality, 100% acrylic paint formulated for exterior use and specifically recommended for fiber cement siding is crucial. These paints offer superior UV resistance, mildew resistance, and flexibility, which are essential for protecting the Hardie board from the elements and preventing premature deterioration. Low-quality paints may fade quickly, crack, or peel, exposing the underlying siding to damage. Following the manufacturer’s recommendations regarding primer and paint application is vital to ensure optimal performance and maximize the lifespan of both the paint and the siding. Using the wrong type of paint could lead to premature paint failure, exposing the Hardie board to the elements and potentially reducing its overall lifespan.

Environmental Considerations

Hardie board, while offering numerous benefits in terms of durability and performance, also carries an environmental footprint that warrants consideration. Understanding its manufacturing process, disposal methods, and comparative impact against alternative materials is crucial for informed building decisions. This section details the environmental aspects of Hardie board, focusing on its lifecycle impact and sustainable practices.

Manufacturing Process and Environmental Impact

The manufacturing of Hardie board involves several stages, each contributing to its overall environmental impact. The extraction and processing of raw materials, primarily cement and cellulose fibers, consume energy and resources. The manufacturing process itself generates emissions, including greenhouse gases like carbon dioxide and particulate matter. Energy consumption during the manufacturing process is a significant factor. However, James Hardie, the primary manufacturer, has implemented various initiatives to reduce its environmental footprint, including investing in energy-efficient technologies and exploring alternative, lower-carbon cement formulations. The specific environmental impact varies depending on the scale of production and the specific technologies employed. For example, facilities utilizing renewable energy sources will have a lower carbon footprint than those reliant on fossil fuels.

Recyclability and Disposal Options

Hardie board is not readily recyclable in the same way as some other materials. However, it is generally considered a durable and long-lasting product, extending its lifespan and minimizing the need for frequent replacements. Disposal options typically involve landfilling, although some regions may have specific guidelines or programs for construction and demolition waste that could include Hardie board. Proper disposal practices are important to minimize environmental impact. Recycling programs for construction waste are becoming more prevalent and often include options for separating and repurposing materials, although Hardie board’s specific recyclability is limited. The focus should be on extending the lifespan of the product through proper maintenance and avoiding premature replacement.

Environmental Footprint Compared to Alternatives

Comparing Hardie board’s environmental footprint to alternatives like wood, vinyl siding, and other cladding materials requires a comprehensive life cycle assessment (LCA). An LCA considers the entire life cycle of a product, from raw material extraction to disposal, evaluating energy consumption, emissions, and waste generation. While a definitive conclusion depends on the specific LCA and the chosen alternatives, studies suggest that Hardie board’s durability can contribute to a lower overall environmental impact compared to materials requiring more frequent replacements. For example, the longevity of Hardie board might offset the initial environmental impact of its manufacturing. The choice of the best material is context-dependent and should consider the specific project needs and local environmental conditions.

Sustainable Sourcing Practices

James Hardie incorporates sustainable sourcing practices into its operations. This includes responsible sourcing of raw materials, aiming to minimize environmental impact and promote sustainable forestry practices. The company’s commitment to sustainability is reflected in its initiatives to reduce water consumption, energy use, and waste generation throughout its production process. Specific details on their sustainable sourcing policies are available on their website and in sustainability reports. These reports often Artikel their progress towards sustainability goals, including targets for reducing emissions and improving resource efficiency. These efforts aim to mitigate the environmental impact associated with the production of Hardie board.

Contribution to Energy Efficiency in Buildings

Hardie board contributes to energy efficiency in buildings primarily through its role as a durable and weather-resistant cladding material. Its ability to resist moisture and temperature fluctuations helps maintain a stable indoor climate, reducing the energy needed for heating and cooling. The improved insulation provided by the product contributes to overall energy efficiency, leading to lower energy consumption and reduced greenhouse gas emissions. Proper installation is key to maximizing the energy-saving benefits of Hardie board. Studies on building energy performance often highlight the role of building materials in reducing energy consumption. In comparison to less effective cladding materials, Hardie board demonstrates a potential for energy savings over its lifetime.

Cost Analysis (excluding labor)

Understanding the cost of 4×8 Hardie board is crucial for accurate budgeting in any construction or renovation project. Several factors influence the final price, including the specific type of siding, the quantity needed, and the retailer from which it’s purchased. This analysis will break down these cost components to provide a clearer picture.

Pricing Factors for 4×8 Hardie Board

The price of 4×8 Hardie board is not uniform. Several key variables significantly affect the final cost per sheet. These factors include the specific product line (e.g., HardiePlank, HardieShingle, HardiePanel), the chosen finish (e.g., smooth, textured, cedar-mimicking), and the overall quantity purchased. Larger orders often qualify for volume discounts, reducing the per-unit cost. Regional variations in pricing are also common, due to transportation costs and local market conditions. Finally, the retailer plays a role; prices can fluctuate between home improvement stores, lumber yards, and online vendors.

Cost Breakdown by Hardie Board Type

Different Hardie board products are designed for various applications and thus carry different price points. For instance, HardiePlank lap siding, a popular choice for its versatility and durability, will typically cost more per sheet than HardiePanel vertical siding, which is often used for simpler applications. The textured finishes, intended to mimic natural wood grains, tend to be slightly more expensive than smooth finishes. To illustrate, a smooth HardiePlank might cost $30-$40 per sheet, while a textured version of the same product might range from $35-$45. These are estimates and will vary based on the retailer and region.

Cost Comparison Across Brands

While James Hardie is the dominant brand in fiber cement siding, other manufacturers offer comparable products. Direct price comparisons can be challenging due to fluctuating market prices and regional differences. However, a general comparison can be made using hypothetical examples based on average market prices. Note that these are estimations and may not reflect actual pricing in all locations.

| Brand | Product Type | Finish | Estimated Price per Sheet ($) |

|---|---|---|---|

| James Hardie | HardiePlank | Smooth | 38 |

| James Hardie | HardieShingle | Textured | 42 |

| [Competitor Brand A] | Comparable Lap Siding | Smooth | 35 |

| [Competitor Brand B] | Comparable Panel Siding | Textured | 30 |

From initial selection and installation to long-term maintenance and environmental impact, understanding 4×8 Hardie board is key to successful construction projects. This guide has provided a comprehensive overview, equipping you with the knowledge to choose, install, and maintain this durable and aesthetically pleasing material. By carefully considering the various factors discussed – including cost, durability, and environmental impact – you can confidently incorporate Hardie board into your next project, ensuring a long-lasting and visually appealing result.

FAQ Compilation

Can Hardie board be used in all climates?

Yes, Hardie board is designed to withstand a wide range of weather conditions, including extreme heat, cold, and humidity. However, proper installation and maintenance are crucial for optimal performance in all climates.

Is Hardie board difficult to cut?

While it’s more durable than wood, Hardie board can be cut with standard woodworking tools like circular saws and jigsaws. However, appropriate safety measures, including dust masks and eye protection, are essential.

What type of paint is best for Hardie board?

100% acrylic paints are generally recommended for Hardie board due to their flexibility and ability to withstand weathering. Always follow the manufacturer’s instructions for paint application.

How long does it take to install 4×8 Hardie board?

Installation time varies significantly depending on project size, complexity, and experience level. A professional installer can complete a smaller project relatively quickly, while larger projects can take considerably longer.

Is Hardie board fire resistant?

Hardie board is a non-combustible material, meaning it won’t readily catch fire and will help slow the spread of flames, making it a safer option than many other cladding materials.