8 Inch aluminum siding offers a durable and aesthetically pleasing exterior cladding solution for homes. This guide delves into the specifics of this material, exploring its dimensions, installation methods, cost considerations, and long-term value. We’ll examine the various advantages and disadvantages, comparing it to other siding options and highlighting its unique properties. From understanding gauge thickness and color choices to mastering installation techniques and addressing potential maintenance issues, we’ll equip you with the knowledge needed to make an informed decision.

We’ll cover everything from choosing the right gauge and color to understanding the installation process, including a step-by-step guide for gable roofs. We’ll also explore the long-term cost-effectiveness, durability in various climates, and even its environmental impact. By the end, you’ll have a complete understanding of 8-inch aluminum siding and its suitability for your project.

Product Specifications

8-inch aluminum siding is a popular choice for homeowners due to its durability, low maintenance, and aesthetic appeal. Understanding its specifications is crucial for making informed decisions during the selection and installation process. This section details the typical dimensions, weight, gauge thicknesses, color options, and a comparison of offerings from different manufacturers.

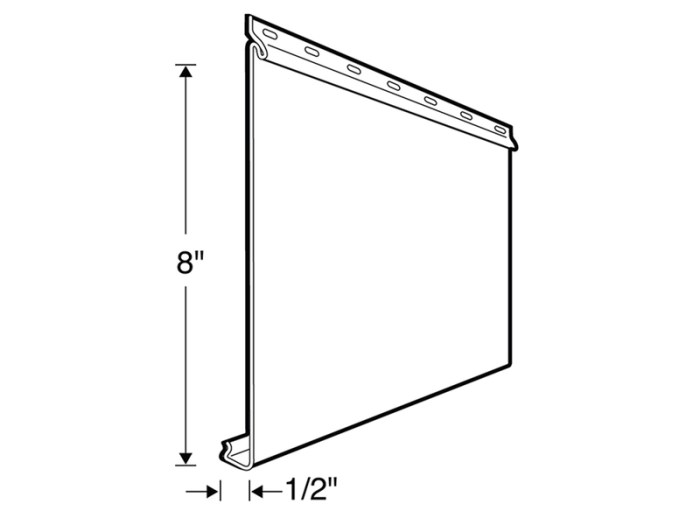

Dimensions and Weight of 8-Inch Aluminum Siding Panels

Standard 8-inch aluminum siding panels typically range in length from 8 to 16 feet. The exact dimensions may vary slightly depending on the manufacturer. Weight is determined by the gauge of the aluminum and the length of the panel; heavier gauge aluminum naturally results in heavier panels. A typical 12-foot panel of medium gauge aluminum might weigh approximately 15-20 pounds, while a heavier gauge panel of the same length would be noticeably heavier. Always consult the manufacturer’s specifications for precise weight and dimension data for specific products.

Gauge Thicknesses of 8-Inch Aluminum Siding

Aluminum siding gauge refers to its thickness. Lower numbers indicate thicker, more durable siding. Common gauge thicknesses for 8-inch aluminum siding range from .032 inches to .050 inches. Thicker gauges offer superior resistance to dents and damage, leading to a longer lifespan. However, thicker gauges also translate to higher costs. The choice of gauge should balance durability needs with budget considerations.

Color Options and Finishes

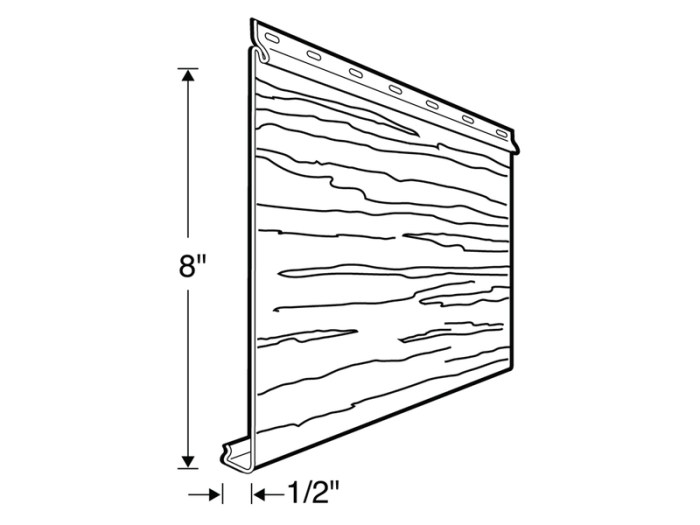

8-inch aluminum siding is available in a wide array of colors and finishes to complement any architectural style. Popular choices include a variety of earth tones, classic whites, and bold colors. Finishes commonly include smooth, textured, and wood-grain options, providing diverse aesthetic possibilities. Many manufacturers offer color-matching services to help homeowners find the perfect shade to match their existing home décor or desired aesthetic. Furthermore, some finishes offer added protection against fading and weathering, extending the siding’s lifespan and maintaining its appearance.

Comparison of 8-Inch Aluminum Siding from Different Manufacturers

The following table compares key features of 8-inch aluminum siding from three hypothetical manufacturers (Manufacturer A, Manufacturer B, and Manufacturer C). Note that specific product offerings and specifications are subject to change, and this table is for illustrative purposes only. Always consult the manufacturer directly for the most up-to-date information.

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Gauge Thickness (inches) | .032, .040, .050 | .032, .040 | .040, .050 |

| Panel Length (feet) | 8, 12, 16 | 10, 12 | 12, 16 |

| Color Options | >50 | >30 | >40 |

| Warranty (years) | 30 | 25 | 35 |

| Finish Options | Smooth, Textured, Woodgrain | Smooth, Textured | Smooth, Woodgrain |

Installation Methods: 8 Inch Aluminum Siding

Installing 8-inch aluminum siding requires careful planning and execution to ensure a long-lasting, aesthetically pleasing result. Proper preparation and adherence to best practices are crucial for achieving a professional finish and avoiding costly mistakes. This section details the process, comparing it to other siding materials and outlining the necessary tools.

The installation of 8-inch aluminum siding generally follows a sequence of steps, from initial preparation to final finishing touches. These steps ensure a secure and weatherproof installation. Understanding these steps is crucial for both DIY enthusiasts and professional installers.

Step-by-Step Guide for 8-Inch Aluminum Siding Installation, 8 inch aluminum siding

This guide Artikels the typical steps involved in installing 8-inch aluminum siding. Remember to always consult the manufacturer’s instructions for specific details and recommendations relevant to the chosen siding product.

- Preparation: Begin by thoroughly cleaning the exterior wall surface, removing any loose paint, debris, or existing siding. Inspect the sheathing for any damage and repair as needed. Ensure the surface is dry and level.

- Installation of Flashing and J-Channel: Install flashing around windows, doors, and other openings to prevent water penetration. J-channel is then installed at the corners and edges of the wall to provide a neat and finished look, as well as a secure starting point for the siding.

- Siding Installation: Starting from the bottom, install the first course of siding, overlapping the bottom edge into the J-channel. Secure the siding using appropriate fasteners, ensuring proper spacing and alignment. Continue installing subsequent courses, overlapping each course by the recommended amount.

- Corner and Trim Installation: Install corner posts and trim pieces to complete the corners and edges of the wall. These pieces provide a clean, finished look and help to protect the edges of the siding.

- Finishing: Once the siding is installed, inspect the installation for any gaps or inconsistencies. Caulk any gaps or seams to ensure a weathertight seal. Clean the siding to remove any debris or excess caulk.

Gable Roof Siding Installation

Installing 8-inch aluminum siding on a gable roof presents unique challenges due to the angled surface. Careful planning and execution are essential to ensure a secure and aesthetically pleasing installation.

- Measuring and Cutting: Accurate measurements are crucial. The siding needs to be cut precisely to fit the angles of the gable roof. Consider using a speed square and a sharp metal-cutting saw for clean cuts.

- Starting Point: Typically, installation begins at the bottom edge of the gable, working upwards. Ensure proper flashing and J-channel are installed before starting the siding installation.

- Overlapping and Securing: Overlapping the siding courses is vital for weather protection. Secure each piece firmly with appropriate fasteners, ensuring they are properly spaced and aligned.

- Ridge Cap Installation: The ridge cap is the final piece installed at the peak of the gable. It protects the top edge of the siding and provides a finished look. Accurate cutting and alignment are critical for a professional finish.

- Finishing Touches: Inspect the installation for any gaps or inconsistencies. Caulk as needed and clean the siding thoroughly.

Comparison of Installation Methods

The installation of 8-inch aluminum siding differs from other siding materials like vinyl in several key aspects. Understanding these differences is essential for choosing the right material and installation method for a specific project.

- Aluminum Siding: Generally requires more specialized tools and expertise due to the need for precise cutting and fastening. It is more durable and resistant to damage but can be more expensive.

- Vinyl Siding: Often easier to install, requiring fewer specialized tools. It is less expensive but can be more susceptible to damage from impact or extreme temperatures.

Necessary Tools and Equipment

Professional installation of 8-inch aluminum siding requires a range of tools and equipment to ensure accuracy, efficiency, and a high-quality finish. Having the right tools on hand minimizes installation time and ensures a professional outcome.

- Measuring Tape

- Metal Snips

- Tin Snips

- Drill with appropriate bits

- Level

- Safety Glasses

- Work Gloves

- Caulk Gun

- Hammer

- Speed Square

- Utility Knife

Material Properties and Durability

Eight-inch aluminum siding offers a compelling blend of aesthetics and practicality for homeowners. Its lightweight yet durable nature makes it a popular choice, but understanding its material properties and comparing it to alternatives is crucial for informed decision-making. This section delves into the advantages and disadvantages of 8-inch aluminum siding, its lifespan, maintenance needs, and its performance against various weather conditions.

Advantages and Disadvantages of 8-Inch Aluminum Siding Compared to Other Options

Aluminum siding boasts several advantages over other materials. Its lightweight nature simplifies installation, reducing labor costs and time. Its inherent resistance to rot, insect infestation, and fire offers significant benefits compared to wood siding. Furthermore, aluminum siding requires minimal maintenance, unlike wood which needs regular painting or staining. However, aluminum siding can dent more easily than vinyl or fiber cement, and its susceptibility to scratches is a potential drawback. The metallic appearance might not appeal to all aesthetic preferences, and its expansion and contraction due to temperature changes can sometimes lead to minor issues if not properly installed. Compared to vinyl, aluminum offers superior durability and longevity but comes at a higher initial cost. Fiber cement siding, while durable, is heavier and more expensive, and may be more susceptible to damage from impacts.

Lifespan and Maintenance Requirements of 8-Inch Aluminum Siding

With proper installation and maintenance, 8-inch aluminum siding can last for 40 years or more. Regular cleaning with soap and water, typically once or twice a year, is sufficient to remove dirt and debris. Addressing minor dents or scratches promptly with touch-up paint can prevent further deterioration. Unlike wood siding, it doesn’t require repainting every few years. However, periodic inspections are recommended to identify and address any potential issues, such as loose panels or damaged fasteners, before they escalate into larger problems. Neglecting maintenance can shorten the lifespan of the siding and lead to more costly repairs. For example, a homeowner who fails to address a minor dent might find that rust develops over time, necessitating replacement of the affected panel.

Resistance of 8-Inch Aluminum Siding to Various Weather Conditions

Aluminum siding exhibits excellent resistance to a wide range of weather conditions. Its ability to withstand extreme temperatures, from scorching summers to freezing winters, makes it suitable for diverse climates. The material’s inherent strength provides significant protection against strong winds. While hail can cause dents, the overall structural integrity is usually maintained. Aluminum’s resistance to moisture and humidity prevents rot and decay, unlike wood siding, which is susceptible to water damage. For instance, in hurricane-prone regions, aluminum siding has proven its resilience against high winds and heavy rainfall, showing less damage than other siding materials in similar situations. However, extreme hailstorms can still cause damage, necessitating repairs or panel replacement.

Potential Issues or Problems Associated with 8-Inch Aluminum Siding Installation and Maintenance

Improper installation is a significant source of problems with aluminum siding. Uneven installation can lead to gaps and allow moisture penetration, potentially causing damage to the underlying structure. Using incorrect fasteners or failing to adequately seal seams can result in leaks. The use of inappropriate caulking or sealant can also lead to failure over time. Furthermore, while aluminum is durable, it can still be damaged by impacts, such as falling branches or hail. The thin gauge of the aluminum can also lead to denting if struck by a hard object. Addressing these issues during installation and through regular maintenance is crucial for ensuring the longevity and performance of the siding. For example, a poorly installed panel might allow water to seep behind it, leading to mold growth and structural damage.

Cost and Value

Choosing the right siding material involves careful consideration of both initial cost and long-term value. 8-inch aluminum siding offers a balance between affordability and durability, but understanding the complete cost picture is crucial for informed decision-making. This section details the cost breakdown, compares it to other options, and identifies factors influencing the final price.

Estimated Costs of Purchasing and Installing 8-Inch Aluminum Siding

The cost of 8-inch aluminum siding installation varies significantly based on several factors, including the size of the house, the complexity of the installation, the chosen color and gauge of the siding, and regional labor costs. A rough estimate for materials alone can range from $2 to $6 per square foot, while labor costs can add another $3 to $8 per square foot. For a 2,000 square foot home, this translates to a potential material cost of $4,000 to $12,000 and labor costs ranging from $6,000 to $16,000. Therefore, the total cost could fall anywhere between $10,000 and $28,000. These are broad estimates; obtaining multiple quotes from reputable contractors is highly recommended for accurate pricing.

Cost-Effectiveness Compared to Other Siding Materials

Comparing the cost-effectiveness of 8-inch aluminum siding to other materials, such as vinyl, fiber cement, and wood, requires a long-term perspective. While vinyl siding might have a lower initial cost, its shorter lifespan (typically 15-20 years) necessitates replacement sooner than aluminum siding, which can last 40-50 years or more with proper maintenance. Fiber cement offers excellent durability, but its initial cost is significantly higher than aluminum. Wood siding, while aesthetically pleasing, demands substantial ongoing maintenance and is susceptible to rot and insect damage, ultimately making it a more expensive option over the long term. A 20-year cost analysis would reveal that, despite potentially higher initial investment, the long lifespan and low maintenance of aluminum siding often make it a cost-effective choice. For example, while vinyl might cost $8,000 initially and need replacement after 15 years ($8,000 again), aluminum siding costing $15,000 initially might only need minor repairs over 20 years, making it a more financially sound decision.

Factors Influencing the Overall Cost of 8-Inch Aluminum Siding Installation

Several key factors influence the overall cost of an 8-inch aluminum siding installation. These include:

| Factor | Impact on Cost | Example |

|---|---|---|

| House Size | Directly proportional; larger houses require more materials and labor. | A 3,000 sq ft house will cost significantly more than a 1,000 sq ft house. |

| Siding Gauge | Thicker gauges (e.g., .032 inch) are more durable but more expensive. | .032 inch gauge siding will cost more than .024 inch gauge siding. |

| Color and Finish | Specialty colors and finishes (e.g., woodgrain) often command higher prices. | A custom-mixed color will be more expensive than a standard color. |

| Installation Complexity | Houses with complex architectural details increase labor costs. | A house with many dormers and intricate trim will cost more to side than a simple ranch. |

| Regional Labor Rates | Labor costs vary widely depending on location. | Installation in a high-cost area like New York City will be more expensive than in a rural area. |

Aesthetic Considerations

Eight-inch aluminum siding offers a surprising versatility in aesthetic applications, capable of complementing a wide range of architectural styles and enhancing curb appeal with thoughtful design choices. Its durability and low maintenance make it a practical choice for homeowners seeking both beauty and longevity. The following sections explore how various design elements contribute to the overall aesthetic impact of 8-inch aluminum siding.

Aluminum Siding and Architectural Styles

The clean lines and smooth surface of 8-inch aluminum siding lend themselves well to modern and contemporary homes. The simplicity of the material allows architectural details like large windows and clean-lined roofs to take center stage. However, with careful color selection and trim work, 8-inch aluminum siding can also complement traditional, craftsman, and even farmhouse styles. The key is to select colors and patterns that harmonize with the existing architectural features and landscaping. For example, a darker, earth-toned siding might suit a craftsman home with its intricate details, while a lighter shade could brighten a traditional home with a more understated design.

Examples of Houses with 8-Inch Aluminum Siding

The versatility of 8-inch aluminum siding is demonstrated through diverse applications.

- A modern home featuring sleek, charcoal-gray 8-inch aluminum siding with crisp white trim and large, expansive windows. The minimal design highlights the home’s clean lines and emphasizes the natural light streaming through the windows.

- A traditional colonial-style home clad in a warm, earthy beige aluminum siding. The siding’s subtle texture is complemented by darker brown trim around the windows and doors, adding depth and visual interest. White columns and shutters further enhance the home’s classic appeal.

- A farmhouse-style home showcasing a muted, light gray aluminum siding. The siding’s subtle texture and color create a calming and rustic aesthetic, enhanced by contrasting black window frames and a dark gray roof. The simplicity of the siding allows the natural wood accents of the home’s porch and landscaping to stand out.

Enhancing Aesthetic Appeal with Trim and Accent Pieces

Strategic use of trim and accent pieces significantly impacts the visual appeal of 8-inch aluminum siding. Different materials, colors, and profiles can create striking contrasts and highlight architectural features.

- Using contrasting colored trim around windows and doors can draw the eye and create visual interest. For example, white or cream trim against a dark gray siding provides a sharp, elegant contrast.

- Adding decorative trim details, such as corner boards or crown molding, adds a touch of sophistication and elevates the overall design. These details can echo architectural styles, creating a cohesive and refined look.

- The use of different metal finishes, such as brushed aluminum or copper, can introduce textural variations and visual interest. These accent pieces can be strategically placed to highlight key features, like entryways or bay windows.

Impact of Siding Patterns and Textures

Aluminum siding is available in a variety of patterns and textures, each impacting the overall aesthetic of a house. The choice of pattern and texture should complement the home’s architectural style and the homeowner’s personal preferences.

- Smooth aluminum siding offers a clean, modern look, ideal for contemporary homes. Its simplicity allows other architectural elements to stand out.

- Textured aluminum siding, mimicking the appearance of wood shake or clapboard, provides a more rustic or traditional aesthetic. This can be a good choice for homes with more ornate details or those in more established neighborhoods.

- Vertical siding creates a taller, more slender appearance, while horizontal siding can make a house appear wider. The choice between vertical and horizontal orientation should consider the house’s proportions and the desired visual effect.

Environmental Impact

Aluminum siding, while offering numerous benefits in terms of durability and aesthetics, presents a complex environmental profile that requires careful consideration. Its lifecycle, from raw material extraction to eventual disposal, influences its overall environmental impact, which should be weighed against the advantages it provides compared to alternative cladding materials. This section explores the environmental aspects of 8-inch aluminum siding, focusing on its recyclability, manufacturing process, and long-term sustainability.

Aluminum siding’s environmental impact is largely determined by its manufacturing process and end-of-life management. The production of aluminum is energy-intensive, requiring significant amounts of electricity to extract aluminum from bauxite ore through the Hall-Héroult process. This process generates greenhouse gas emissions, primarily carbon dioxide, which contribute to climate change. However, aluminum’s high recyclability mitigates this impact to a significant degree. Recycled aluminum requires significantly less energy to produce compared to primary aluminum, making it a more environmentally friendly option.

Aluminum Siding Recyclability and Comparison to Other Materials

Aluminum siding boasts a remarkably high recyclability rate. Unlike vinyl siding, which often ends up in landfills, aluminum can be repeatedly recycled without significant loss of quality. This characteristic significantly reduces the demand for newly mined bauxite, lessening the environmental burden associated with mining and processing. Compared to wood siding, which requires extensive forestry and can be susceptible to rot and insect damage, aluminum offers a longer lifespan and reduced need for replacement, thereby minimizing the ongoing environmental impact. While materials like fiber cement offer some eco-friendly aspects, aluminum’s recyclability offers a distinct advantage in terms of resource conservation.

Manufacturing Process and Environmental Footprint of 8-Inch Aluminum Siding

The manufacturing process of 8-inch aluminum siding begins with the sourcing of aluminum ingots, often from recycled sources. These ingots are then melted and rolled into sheets of the desired thickness. The sheets are subsequently coated with protective layers, typically paint or a similar finish, to enhance durability and aesthetics. The entire process involves energy consumption, water usage, and the generation of waste materials. However, advancements in manufacturing techniques, such as the increased use of recycled aluminum and more efficient energy sources, are continually working to minimize the environmental footprint. For example, some manufacturers are implementing processes that reduce energy consumption by 20% compared to traditional methods, while others focus on reducing water usage by 15%. These improvements demonstrate a commitment to environmental responsibility within the industry.

Potential Environmental Benefits and Drawbacks of 8-Inch Aluminum Siding

A significant benefit of aluminum siding is its longevity. Its durability and resistance to the elements translate into a longer lifespan compared to many alternatives, reducing the frequency of replacement and associated environmental impacts. The high recyclability of aluminum at the end of its service life further minimizes its environmental footprint. However, the energy-intensive nature of aluminum production remains a drawback. The manufacturing process contributes to greenhouse gas emissions and requires substantial resources. Furthermore, the production and application of coatings and paints used on aluminum siding can introduce additional environmental concerns, depending on their composition and disposal methods.

Long-Term Sustainability of 8-Inch Aluminum Siding

The long-term sustainability of 8-inch aluminum siding depends on several factors, including the proportion of recycled aluminum used in its production, the efficiency of the manufacturing process, and the effectiveness of end-of-life recycling programs. The increasing availability of recycled aluminum and ongoing improvements in manufacturing technologies are contributing to a more sustainable production process. Furthermore, robust recycling infrastructure and consumer awareness of the importance of recycling aluminum siding are crucial for maximizing its long-term environmental benefits. A commitment to responsible sourcing, efficient manufacturing, and effective recycling is essential for ensuring that aluminum siding contributes to a more sustainable built environment.

Ultimately, the decision to use 8-inch aluminum siding hinges on a careful consideration of its numerous benefits against potential drawbacks and individual project requirements. While its durability, low maintenance, and recyclability are strong selling points, factors such as initial cost and aesthetic preferences must also be weighed. This comprehensive guide provides the necessary information to facilitate a well-informed decision, empowering homeowners and contractors alike to make the best choice for their specific needs. Understanding the material’s properties, installation process, and long-term value is key to maximizing your investment and achieving a beautiful, long-lasting exterior.

Key Questions Answered

What is the average lifespan of 8-inch aluminum siding?

With proper maintenance, 8-inch aluminum siding can last 40-50 years or more.

Is 8-inch aluminum siding difficult to install?

While manageable for DIYers with experience, professional installation is often recommended for optimal results and warranty coverage.

Can 8-inch aluminum siding be painted?

Yes, but it’s generally not necessary due to the durability of the factory-applied finishes. If repainting is desired, use a paint specifically designed for aluminum.

How does 8-inch aluminum siding compare to vinyl siding in terms of noise reduction?

Aluminum siding generally offers better noise reduction than vinyl siding due to its denser material.

Does 8-inch aluminum siding require special cleaning?

Regular cleaning with soap and water is sufficient. Avoid abrasive cleaners.