Metal fascia trim elevates building aesthetics and functionality. From sleek modern designs to classic architectural styles, its versatility shines through diverse applications. This guide delves into the various types of metal fascia trim, exploring material properties, installation techniques, maintenance considerations, and design implications to help you make informed choices for your next project. We’ll examine the durability, cost-effectiveness, and environmental impact of different options, ensuring you understand the complete picture before making a decision.

We’ll cover everything from the practical aspects of installation and maintenance to the aesthetic considerations that can transform a building’s exterior. Learn how to select the perfect metal fascia trim to complement your architectural vision while maximizing energy efficiency and weather protection. Discover how this seemingly small detail can make a significant difference in the overall look, feel, and longevity of your structure.

Types of Metal Fascia Trim

Metal fascia trim offers a durable and aesthetically pleasing solution for a variety of architectural and industrial applications. The choice of material significantly impacts the longevity, appearance, and overall cost of the project. Understanding the properties and characteristics of different metal types is crucial for making informed decisions.

Metal Materials Used in Fascia Trim Manufacturing

Several metals are commonly employed in the production of fascia trim, each possessing unique properties that dictate their suitability for specific applications. Aluminum, steel, and stainless steel are among the most prevalent choices. Aluminum is lightweight, corrosion-resistant, and readily formable, making it a popular option for various architectural projects. Steel, while heavier and potentially more susceptible to rust, offers superior strength and is often cost-effective for larger-scale applications. Stainless steel combines the strength of steel with exceptional corrosion resistance, making it ideal for demanding environments.

Comparison of Durability and Aesthetic Qualities

The durability and aesthetic qualities of different metal fascia trim types vary considerably. Aluminum fascia trim, while lightweight, is highly resistant to corrosion and can be easily shaped into intricate designs. However, it may dent more easily than steel. Steel fascia trim provides exceptional strength and durability, but requires proper surface treatment to prevent rusting. Stainless steel offers the best combination of strength, corrosion resistance, and longevity, though it is typically the most expensive option. Aesthetically, each material can achieve a wide range of finishes, allowing for considerable design flexibility.

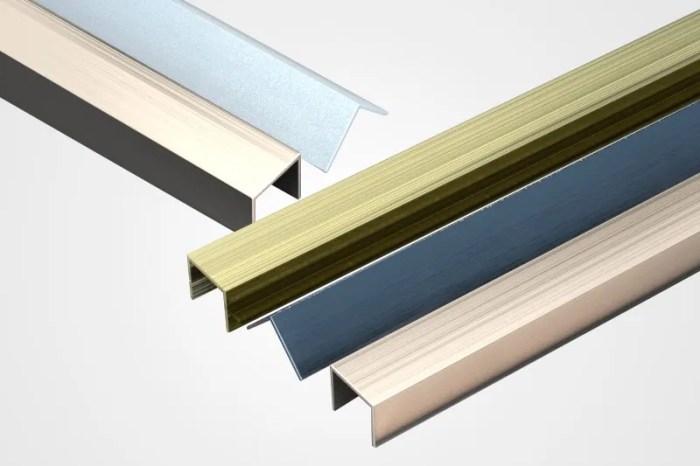

Metal Fascia Trim Finishes

A wide array of finishes enhances the appearance and protective qualities of metal fascia trim. Powder coating provides a durable, even finish in a vast array of colors and textures, offering excellent protection against corrosion and UV degradation. Imagine a deep, matte black powder-coated aluminum trim, providing a sleek, modern look while resisting the elements. Anodizing creates a hard, corrosion-resistant layer directly on the aluminum surface, resulting in a subtle, often metallic sheen. A brushed stainless steel finish, on the other hand, offers a more industrial, textured look with a subtle metallic shimmer, showcasing the material’s inherent beauty.

Cost, Lifespan, and Maintenance Comparison

| Material | Cost | Lifespan (Years) | Maintenance |

|---|---|---|---|

| Aluminum | Medium | 30-50+ | Low; occasional cleaning |

| Steel (Galvanized) | Low to Medium | 20-40 | Medium; periodic inspection and repainting |

| Stainless Steel | High | 50+ | Low; occasional cleaning |

Applications of Metal Fascia Trim

Metal fascia trim, with its durability and aesthetic versatility, finds extensive use in a variety of architectural applications, enhancing both the visual appeal and structural integrity of buildings. Its inherent strength and resistance to the elements make it a superior choice compared to traditional materials in many situations.

Architectural Applications of Metal Fascia Trim

Metal fascia trim plays a crucial role in several key architectural elements. Its use in roofing, siding, and soffits provides significant benefits in terms of longevity, weather resistance, and aesthetic enhancement. The specific advantages vary depending on the application. For instance, on roofs, it protects the underlying structure from water damage and adds a finished, professional look. On siding, it creates a clean, crisp edge, protecting the siding material itself from damage. And on soffits, it provides a neat, protective barrier against the elements, enhancing the overall appearance of the building’s underside.

Metal Fascia Trim in Different Building Styles

The adaptability of metal fascia trim allows its seamless integration into diverse architectural styles. In modern architecture, sleek, minimalist designs often incorporate brushed stainless steel or aluminum fascia trim to create clean lines and a contemporary aesthetic. Think of a glass-fronted office building where the sharp lines of the metal trim complement the building’s geometric structure. Traditional styles, on the other hand, might utilize copper or zinc fascia trim with aged finishes to achieve a more rustic, timeworn look, fitting in with the detailing found on historic homes. Industrial-style buildings frequently feature exposed metalwork, and metal fascia trim in dark, matte finishes like black powder-coated steel further enhances this aesthetic, complementing the raw, functional character of the building.

Contribution of Metal Fascia Trim to Building Energy Efficiency and Weather Protection

Metal fascia trim contributes significantly to a building’s energy efficiency and weather protection. Its inherent durability protects the underlying building materials from the damaging effects of wind, rain, snow, and sun. Furthermore, properly installed metal fascia trim helps to prevent water intrusion, reducing the risk of mold and rot. This contributes to a more energy-efficient building because less energy is needed to maintain a stable internal temperature and humidity. The use of reflective metal finishes can further enhance energy efficiency by reflecting solar radiation, reducing heat gain in warmer climates. Properly sealed and insulated connections between the fascia and other building components minimize air leakage, further enhancing energy performance.

Hypothetical Building Facade Incorporating Metal Fascia Trim

Imagine a three-story mixed-use building with a modern industrial aesthetic. The facade features large expanses of glass interspersed with panels of dark gray, textured concrete. A dark bronze powder-coated aluminum fascia trim is used to frame the glass panels and delineate the edges of the concrete sections. The trim is seamlessly integrated with the building’s structural elements, creating a visually striking yet functional design. The bronze finish provides a subtle contrast to the gray concrete and dark windows, while the metal’s durability ensures long-lasting protection for the building’s exterior. The trim is carefully detailed at corners and intersections, creating a clean, professional finish. The building’s rooftop is capped with a matching bronze metal fascia, enhancing the building’s overall cohesiveness.

Installation and Maintenance of Metal Fascia Trim

Proper installation and regular maintenance are crucial for ensuring the longevity and aesthetic appeal of metal fascia trim. Neglecting these aspects can lead to premature corrosion, damage, and costly repairs. This section details the necessary steps for both installation and upkeep, highlighting best practices to maximize the lifespan of your metal fascia trim.

Metal Fascia Trim Installation

Installing metal fascia trim requires precision and attention to detail. Improper installation can compromise its effectiveness and appearance. The process generally involves several key steps, beginning with preparation and ending with final securing. Appropriate safety measures must be taken throughout the entire process.

- Preparation: Accurate measurements are paramount. Begin by carefully measuring the area requiring trim, accounting for overlaps and cuts. Ensure the surface is clean, dry, and free from any debris or loose paint. Necessary tools include a measuring tape, level, tin snips or shears, safety glasses, and work gloves.

- Cutting and Fitting: Use appropriate cutting tools to accurately cut the metal fascia trim to the required lengths. Dry-fit the pieces before securing them to ensure a proper fit and alignment. Adjustments can be made during this stage to avoid costly mistakes later.

- Securing the Trim: Once the fit is confirmed, secure the trim using appropriate fasteners, such as screws or rivets. Ensure fasteners are correctly spaced and driven to avoid damaging the trim. The type of fastener and spacing will depend on the material and profile of the trim.

- Caulking and Sealing: After securing the trim, apply a high-quality sealant or caulk to all joints and seams to prevent water penetration and ensure a weathertight seal. This step is critical in preventing corrosion.

- Final Inspection: Conduct a thorough inspection to ensure proper alignment, secure fastening, and complete sealing. Address any imperfections immediately to prevent future problems.

Metal Fascia Trim Maintenance

Regular maintenance is key to prolonging the life of your metal fascia trim and maintaining its appearance. This includes routine cleaning and addressing any signs of damage promptly.

- Cleaning: Regularly clean the trim using a soft brush, mild detergent, and water. Avoid abrasive cleaners or harsh chemicals, which can damage the surface finish. Rinse thoroughly and allow to dry completely.

- Inspection: Periodically inspect the trim for any signs of damage, such as dents, scratches, or corrosion. Address minor issues promptly to prevent them from escalating.

- Repairing Minor Damage: Minor dents or scratches can often be repaired using touch-up paint that matches the trim’s finish. For more significant damage, professional repair may be necessary.

- Corrosion Prevention: Apply a protective coating, such as a sealant or rust inhibitor, to exposed metal edges or areas prone to corrosion. This is especially important in coastal or humid environments.

Common Problems and Solutions

Several issues can arise during the installation and maintenance of metal fascia trim. Understanding these potential problems and their solutions can help prevent costly repairs and ensure a successful outcome.

- Problem: Improperly cut trim resulting in gaps or misalignment. Solution: Careful measurement and cutting using appropriate tools are crucial. Dry-fitting before final installation can prevent this issue.

- Problem: Loose or missing fasteners leading to trim detachment. Solution: Ensure fasteners are correctly installed and adequately spaced. Use appropriate fasteners for the material and thickness of the trim.

- Problem: Water penetration causing corrosion. Solution: Proper sealing and caulking of joints and seams is vital. Regular inspection and prompt repair of any damage can prevent this issue.

- Problem: Surface damage due to harsh cleaning agents. Solution: Use only mild detergents and soft brushes when cleaning. Avoid abrasive cleaners or harsh chemicals.

Design Considerations for Metal Fascia Trim

The aesthetic appeal and longevity of a building are significantly impacted by the choice of exterior materials, and metal fascia trim plays a crucial role in this. Careful consideration of design elements, including profile, color, and integration with the surrounding environment, is essential for achieving a visually harmonious and structurally sound result. This section explores key design considerations to ensure your metal fascia trim enhances, rather than detracts from, your building’s overall design.

Aesthetic Impact of Metal Fascia Trim Profiles and Colors

Metal fascia trim offers a wide variety of profiles, from simple, straight lines to more intricate, decorative designs. The chosen profile significantly affects the overall aesthetic. A sleek, minimalist profile, for example, might suit a modern, contemporary building, while a more ornate profile could complement a traditional or Victorian-style structure. Similarly, color choices dramatically impact the visual impression. Darker colors, such as charcoal grey or deep bronze, can create a sense of sophistication and drama, while lighter colors, like silver or white, can offer a brighter, more airy feel. The interplay between profile and color allows for extensive customization to match the building’s architectural style and the desired mood. For instance, a building with a rustic design could use a weathered copper fascia trim with a slightly textured profile, whereas a contemporary high-rise might opt for a smooth, brushed aluminum finish with a simple, rectangular profile.

Environmental Considerations in Metal Fascia Trim Selection

The surrounding environment plays a critical role in selecting appropriate metal fascia trim. Factors such as climate, local building codes, and the overall landscape should be considered. In coastal areas, for instance, corrosion resistance is paramount, making materials like stainless steel or aluminum with appropriate coatings highly suitable. In areas with extreme temperature fluctuations, the thermal expansion and contraction properties of the chosen metal must be carefully considered to prevent warping or damage. Furthermore, the color of the trim should complement the natural environment. A dark-colored trim might absorb more heat in a hot climate, potentially affecting the building’s energy efficiency. Conversely, a lighter color might reflect more sunlight, contributing to energy savings. Careful consideration of these factors ensures the longevity and aesthetic appeal of the fascia trim within its specific environment.

Visual Comparison of Metal Fascia Trim with Other Materials

Metal fascia trim offers several advantages over other materials, such as wood or vinyl. Unlike wood, which requires regular maintenance and is susceptible to rot and insect damage, metal is highly durable and requires minimal upkeep. Compared to vinyl, metal offers a more sophisticated and often more durable appearance, particularly in harsh weather conditions. While wood can provide a warm, natural aesthetic, metal can offer a clean, modern, or industrial look, depending on the chosen finish and profile. Vinyl, while affordable, often lacks the visual richness and longevity of metal. The choice ultimately depends on the desired aesthetic and the priorities of the building owner, balancing cost, maintenance, and aesthetic preferences.

Seamless Integration of Metal Fascia Trim into Building Design

Successfully integrating metal fascia trim into a building’s overall design scheme involves careful planning and coordination. The trim’s color and profile should complement the building’s exterior materials, such as siding, roofing, and windows. The trim should not clash with these elements but rather enhance them, creating a cohesive and visually appealing whole. For example, a building with brick siding might use a metal fascia trim with a color that complements the brick’s tones. Similarly, a building with a modern, glass façade might benefit from a sleek, minimalist metal trim in a complementary metallic shade. Careful attention to detail, including consistent lines and proper installation, ensures the trim seamlessly blends with the building’s architectural style and enhances its overall appearance.

Sustainability and Environmental Impact: Metal Fascia Trim

Metal fascia trim, while offering durability and aesthetic appeal, presents considerations regarding its environmental impact. Understanding the lifecycle of these materials, from production to disposal, is crucial for responsible building practices. This section explores the sustainability aspects of metal fascia trim, comparing it to alternatives and outlining strategies for environmentally conscious choices.

The environmental footprint of metal fascia trim is largely determined by the material used, its manufacturing process, and its eventual end-of-life management. Steel, aluminum, and zinc are common choices, each possessing unique environmental profiles. Steel production, for instance, is energy-intensive, but steel is highly recyclable with minimal loss of material properties. Aluminum boasts superior recyclability and requires less energy for recycling than for primary production. Zinc, while also recyclable, has a more complex recycling process.

Recyclability and Environmental Impact of Materials

Steel, aluminum, and zinc, the primary metals used in fascia trim, exhibit varying degrees of recyclability. Steel boasts a high recyclability rate, with minimal degradation in material quality after multiple recycling cycles. This makes it a relatively sustainable choice. Aluminum also boasts exceptional recyclability, requiring significantly less energy to recycle than to produce from raw bauxite ore. Zinc recycling is more complex and less efficient compared to steel and aluminum, impacting its overall sustainability profile. The environmental impact of each metal also extends to the mining and processing of raw materials, transportation, and manufacturing processes. These factors need to be considered holistically when assessing the overall environmental performance.

Comparison with Alternative Materials

Compared to alternative materials like vinyl or wood, metal fascia trim presents both advantages and disadvantages concerning environmental impact. Vinyl, derived from petroleum, is not readily biodegradable and its production contributes to greenhouse gas emissions. Wood, while a renewable resource, can be sourced unsustainably leading to deforestation and habitat loss. Metal fascia trim, particularly when made from recycled materials, offers a more durable and potentially more sustainable option, especially considering its longevity and recyclability. However, the initial energy input for metal production remains a factor to consider in the overall life cycle assessment. A comprehensive life cycle analysis comparing these materials is needed to provide a definitive conclusion on which option is most sustainable in a given context.

Sustainable Manufacturing Practices

Sustainable manufacturing practices play a vital role in minimizing the environmental impact of metal fascia trim production. Using recycled metal content significantly reduces the need for virgin materials, thus lowering energy consumption and greenhouse gas emissions. Implementing energy-efficient manufacturing processes, such as optimized furnace operation and waste heat recovery, can also contribute to a smaller carbon footprint. Furthermore, responsible waste management, including the reduction, reuse, and recycling of production waste, is essential for minimizing environmental impact. Investing in cleaner production technologies and minimizing water usage are also crucial steps towards more sustainable manufacturing.

Factors to Consider When Choosing Environmentally Friendly Metal Fascia Trim

Choosing environmentally friendly metal fascia trim requires careful consideration of several factors.

- Material Selection: Prioritize recycled content. Aluminum and steel, with their high recyclability rates, are generally preferable to zinc.

- Manufacturing Processes: Look for manufacturers committed to sustainable practices, including energy efficiency and waste reduction.

- Product Longevity: A longer-lasting product reduces the need for frequent replacements, minimizing the overall environmental impact over time.

- End-of-Life Management: Ensure the chosen material is readily recyclable and that appropriate recycling infrastructure exists in your region.

- Transportation: Consider the distance the material travels from its point of origin to the installation site, to minimize carbon emissions related to transportation.

- Life Cycle Assessment (LCA): If possible, obtain and review the LCA of the product to understand its complete environmental profile.

Metal fascia trim offers a compelling blend of aesthetics, durability, and sustainability. By carefully considering the material, finish, and installation, you can significantly enhance your building’s appearance and longevity. Understanding the various options and their associated benefits empowers you to make informed decisions that align with both your design vision and environmental responsibility. From selecting the right material to ensuring proper maintenance, this guide provides the knowledge needed to successfully integrate metal fascia trim into your next project, resulting in a structure that is both visually stunning and built to last.

Quick FAQs

What is the average lifespan of metal fascia trim?

Lifespan varies greatly depending on the material (aluminum, steel, stainless steel) and finish, ranging from 20 to 50+ years with proper maintenance.

Can metal fascia trim be painted?

Yes, but proper surface preparation is crucial. Powder-coated trims generally shouldn’t be repainted, while other types may require specific primers and paints for optimal adhesion and longevity.

How do I clean metal fascia trim?

Regular cleaning with mild soap and water is usually sufficient. Avoid abrasive cleaners. For stubborn stains, consult the manufacturer’s recommendations.

Are there specific building codes regarding metal fascia trim?

Yes, building codes vary by location. Check with your local authorities for specific regulations regarding material specifications, installation methods, and fire safety requirements.

What are the potential risks associated with improper installation?

Improper installation can lead to leaks, damage to the underlying structure, premature corrosion, and compromised aesthetics. Always follow manufacturer instructions and consider professional installation.