Joist hangers 2×6 are essential components in any construction project involving 2×6 lumber. Understanding their various types, installation techniques, and load-bearing capacities is crucial for ensuring structural integrity and safety. This guide delves into the intricacies of 2×6 joist hangers, providing a comprehensive overview for both professionals and DIY enthusiasts. From selecting the right hanger for your specific application to mastering proper installation techniques, we’ll cover everything you need to know to work confidently with these vital structural elements.

We’ll explore the different types of joist hangers available, comparing their strengths, weaknesses, and suitability for various applications. We’ll also examine crucial aspects like load capacity calculations, code compliance, material selection, and troubleshooting common installation issues. By the end of this guide, you’ll be equipped with the knowledge to select, install, and maintain 2×6 joist hangers effectively, contributing to robust and secure structures.

Joist Hanger Types for 2×6 Lumber

Selecting the appropriate joist hanger for 2×6 lumber is crucial for ensuring structural integrity and safety in any construction project. The choice depends on factors such as the load-bearing requirements, the type of connection, and the specific application. Understanding the different types available and their characteristics is essential for making informed decisions.

Joist Hanger Material Composition and Load Capacity

Joist hangers for 2×6 lumber are typically manufactured from either galvanized steel or stamped steel. Galvanized steel offers superior corrosion resistance, making it ideal for outdoor or humid environments. Stamped steel hangers are generally more cost-effective but may require additional corrosion protection in certain conditions. The load-bearing capacity of a joist hanger is determined by its design, material, and the size of the lumber it supports. Manufacturers provide load tables specifying the safe working load for each hanger type under various conditions. These tables consider factors such as the species of lumber, span length, and the hanger’s connection to the supporting member. Always consult the manufacturer’s specifications before selecting and installing a joist hanger. Exceeding the stated load capacity can compromise structural integrity and lead to failure.

Comparison of Joist Hanger Designs

Several joist hanger designs are available for 2×6 lumber, each with its own strengths and weaknesses. Common designs include: standard joist hangers, which provide a basic connection; reinforced joist hangers, designed for increased load capacity; and joist hangers with built-in nailing surfaces for easier installation. Standard joist hangers are suitable for many applications but may not be adequate for heavier loads or complex connections. Reinforced hangers offer greater load-bearing capacity and are preferable for situations with significant weight. Joist hangers with built-in nailing surfaces simplify installation and ensure a secure connection. The choice of design depends on the specific requirements of the project, considering factors like load, span, and ease of installation. For example, in a situation with heavy loads, like a second-floor joist system, a reinforced joist hanger would be a safer and more appropriate choice.

Joist Hanger Installation Methods and Safety Precautions

Proper installation of joist hangers is critical for ensuring the structural integrity and safety of the building. The installation process generally involves aligning the hanger with the joist and the supporting member, ensuring proper seating and alignment, and securing it with appropriate nails or screws. Manufacturers typically provide detailed installation instructions, including recommended nail or screw sizes and patterns. Safety precautions include using appropriate personal protective equipment (PPE), such as safety glasses and work gloves. Always ensure the supporting member is properly sized and capable of supporting the load. Inspect hangers for any damage before installation and avoid using damaged or bent hangers. Ensure proper alignment to prevent uneven load distribution and potential failure. Improper installation can lead to structural weakness and potential collapse, emphasizing the importance of careful adherence to manufacturer’s instructions and safety guidelines.

Comparison of 2×6 Joist Hanger Types

| Hanger Type | Dimensions (in) | Material | Load Capacity (lbs) | Typical Applications |

|---|---|---|---|---|

| Standard Joist Hanger | Variable, depending on manufacturer | Galvanized Steel | Variable, depending on manufacturer and load table | General purpose framing, light to moderate loads |

| Reinforced Joist Hanger | Variable, generally larger than standard | Galvanized Steel | Higher than standard hangers, check manufacturer’s specifications | Heavier loads, longer spans, critical structural applications |

| Hurricane Tie Joist Hanger | Variable, designed for specific connection types | Galvanized Steel | High load capacity, designed for wind resistance | High-wind areas, seismic zones, critical structural applications |

| Heavy-Duty Joist Hanger | Larger dimensions, thicker gauge steel | Galvanized Steel | Significantly higher load capacity compared to standard hangers | Very heavy loads, industrial applications, specialized framing |

Installation Techniques for 2×6 Joist Hangers

Proper installation of 2×6 joist hangers is crucial for ensuring the structural integrity and safety of any building project. Incorrect installation can lead to significant structural weaknesses, potentially resulting in costly repairs or even collapse. This section details the correct techniques for installing these hangers, emphasizing alignment, fastening, and error identification.

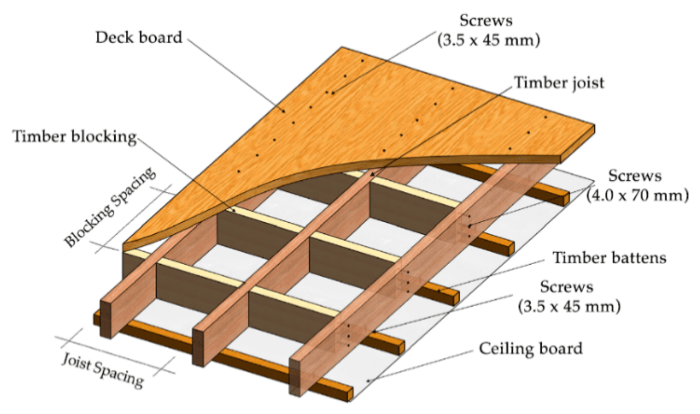

Joist Hanger Placement and Orientation

Accurate placement and orientation of the joist hanger are paramount. The hanger’s design must match the dimensions of both the joist and the supporting beam. The hanger should be positioned so that the joist rests fully and evenly within the hanger’s cradle. Misalignment can lead to uneven weight distribution and stress concentration on specific points, compromising the hanger’s load-bearing capacity. The hanger should be properly seated against the supporting beam, ensuring complete contact across its entire surface. Incorrect orientation can lead to the joist pulling away from the beam, weakening the structure. Imagine a seesaw; if the fulcrum (the hanger) isn’t centered and secure, the balance (structural integrity) is compromised.

Fastening Techniques for Secure Joist Hanger Installation

Secure fastening is achieved through the use of appropriately sized nails or screws, driven straight and deep into both the joist and the supporting beam. The manufacturer’s instructions should always be followed meticulously regarding the number, type, and placement of fasteners. Using too few fasteners or driving them at an angle will reduce the hanger’s holding power. Conversely, using the wrong type of fastener or overdriving them can damage the wood, compromising its strength. A visual representation would show nails driven perpendicularly into both the joist and the beam, fully penetrating the hanger’s designated nail holes. The nails should be evenly spaced and deeply embedded to provide maximum holding power.

Step-by-Step Guide to Installing 2×6 Joist Hangers

- Preparation: Ensure the supporting beam is level and properly sized. Check the joist for any damage or warping. Select the correct joist hanger for your lumber dimensions.

- Positioning: Place the hanger against the supporting beam, ensuring it is aligned correctly. The joist should sit squarely within the hanger’s cradle.

- Pre-drilling (Optional): For hardwoods or to prevent splitting, pre-drilling pilot holes is recommended. This step reduces the risk of the wood splitting when the nails are hammered in.

- Fastening: Drive the nails or screws into the designated holes, ensuring they are fully seated. Use a nail gun for efficient and consistent fastening, or a hammer for manual installation. Check the manufacturer’s instructions for the specific number and type of fasteners required.

- Verification: After fastening, visually inspect the installation. The joist should be securely held within the hanger, with no visible gaps or misalignment.

Imagine a diagram showing each step: (1) a level beam and a 2×6 joist; (2) the hanger correctly positioned on the beam; (3) pre-drilled holes in the joist and beam; (4) nails driven straight and fully into both the joist and beam through the hanger; (5) the final secure installation, showing the joist firmly held in the hanger.

Identifying and Addressing Common Installation Errors

Common errors include improper hanger alignment, insufficient fastening, and using the wrong type of hanger. Improper alignment leads to uneven weight distribution, concentrating stress on particular points. Insufficient fastening reduces the hanger’s load-bearing capacity, potentially leading to failure. Using the wrong type of hanger, such as one not designed for 2×6 lumber, will compromise the structural integrity of the entire system. Addressing these errors involves removing the incorrectly installed hanger and repeating the installation process, paying close attention to detail and ensuring proper alignment and adequate fastening. For example, if a hanger is found to be misaligned, it must be removed and reinstalled to ensure the joist sits correctly within the hanger’s cradle.

Load Capacity and Structural Considerations: Joist Hangers 2×6

Understanding the load-bearing capacity of 2×6 joist hangers is crucial for ensuring the structural integrity of any building project. This involves considering several interacting factors, including the hanger type, joist spacing, lumber grade, and the anticipated load. Incorrect calculations can lead to structural failure, posing significant safety risks. Therefore, accurate assessment and appropriate hanger selection are paramount.

The load capacity of a joist hanger system is not solely determined by the hanger itself; it’s a complex interplay of various elements. This section details the key factors influencing load capacity and provides examples to illustrate practical application.

Joist Hanger Load Capacity Calculations

Calculating the load capacity of a 2×6 joist hanger configuration requires considering the span of the joist, the spacing between joists, the type of joist hanger used, and the lumber grade. Manufacturers provide load tables specifying the safe working load for various hanger types and lumber sizes under specific conditions. These tables are usually found in manufacturer’s catalogs or online resources. For example, a standard joist hanger designed for a 2×6 joist might have a load capacity of 1000 lbs when the joists are spaced 16 inches apart and using a specific grade of lumber. However, increasing the joist spacing to 24 inches might reduce the load capacity to 750 lbs for the same hanger and lumber. It’s crucial to always consult the manufacturer’s load tables for precise values. Calculations often involve using engineering formulas considering the material properties of the lumber and the geometry of the hanger and joist system. These formulas are complex and best left to structural engineers, however, understanding the impact of each variable is critical for proper selection.

Factors Influencing Joist Hanger Load Capacity

Several factors significantly influence the load-bearing capacity of a 2×6 joist hanger system. Understanding these factors is vital for selecting the appropriate hangers and ensuring structural safety.

- Joist Spacing: Closer joist spacing distributes the load more effectively, increasing the overall load capacity of the system. Wider spacing increases stress on each joist and hanger, thus reducing the load capacity. For instance, a system with 12-inch joist spacing will generally support a heavier load than a system with 24-inch spacing.

- Joist Hanger Type: Different joist hanger designs offer varying load capacities. For example, a heavy-duty joist hanger will typically support a significantly larger load than a standard hanger. Specialty hangers exist for specific applications, such as those designed for sloped ceilings or unusual load distributions.

- Lumber Grade: The grade of lumber used for the joists directly impacts its strength and stiffness. Higher-grade lumber (e.g., No. 1 or better) offers superior strength and will therefore allow for higher load capacities compared to lower-grade lumber. Using lower grade lumber necessitates either closer joist spacing or stronger hangers.

- Load Type: The type of load (live or dead) also influences the required load capacity. Live loads are dynamic (e.g., people, furniture), while dead loads are static (e.g., the weight of the joist itself). Live loads often require a larger safety factor in the design.

- Environmental Conditions: Exposure to moisture or extreme temperatures can degrade lumber strength over time, impacting the load-bearing capacity of the joist hanger system. Proper protection against moisture and temperature extremes is essential for maintaining structural integrity.

Situations Requiring Stronger or Specialized Joist Hangers

In situations with heavier loads or unique structural requirements, stronger or specialized joist hangers may be necessary. Examples include:

* Heavy loads: Supporting heavy machinery or equipment in industrial settings requires robust hangers with significantly higher load capacities.

* Long spans: Longer joist spans necessitate stronger hangers to accommodate the increased bending moments.

* Complex geometries: Unusual ceiling angles or complex framing arrangements might require specialized hangers designed for specific applications.

* Seismic zones: Areas prone to earthquakes require hangers designed to withstand lateral forces.

* High-humidity environments: In environments with consistently high humidity, corrosion-resistant hangers might be needed to prevent premature failure.

Code Compliance and Building Regulations

Adherence to building codes and regulations is paramount when installing joist hangers, ensuring structural integrity and occupant safety. Failure to comply can lead to significant legal and financial repercussions. This section details code compliance requirements specifically for 2×6 joist hanger installations in residential construction.

Building codes, such as the International Building Code (IBC) and local amendments, dictate the acceptable methods and materials for joist hanger installations. These codes specify minimum load capacities, proper fastening techniques, and acceptable hanger types based on factors like span length, joist size, and anticipated loads (live and dead). Specific requirements can vary depending on geographic location and the type of construction.

Identifying Relevant Building Codes

Determining the applicable building codes for your project is the first step. This typically involves contacting your local building department or referencing online resources that provide access to your jurisdiction’s adopted codes. The IBC serves as a widely adopted model code, but local jurisdictions often incorporate amendments and modifications to address specific regional needs and conditions. Understanding the precise requirements of your local codes is crucial for ensuring compliance.

Selecting Code-Compliant Joist Hangers, Joist hangers 2×6

Selecting appropriate joist hangers involves careful consideration of several factors. Manufacturers provide load capacity data for their hangers, often specifying the allowable loads for different lumber sizes and hanger configurations. This data should be cross-referenced with the load calculations for your specific project, which must meet or exceed the requirements Artikeld in the relevant building codes. Hangers should always be selected to support the calculated loads, accounting for safety factors. Using a hanger with a load capacity less than the calculated load is a violation of building codes and poses significant structural risks.

Documentation for Code Compliance

Maintaining thorough documentation is essential to demonstrate compliance with building codes. This documentation should include: a copy of the applicable building codes, detailed load calculations showing the anticipated loads on the joists, specifications of the selected joist hangers (manufacturer, model number, load capacity), and photographs or other visual evidence documenting the proper installation of the hangers. This documentation should be kept on file and readily available for inspection by building officials.

Building Code Requirements for 2×6 Joist Hanger Installations

The following table provides a simplified example of building code requirements. Note that these values are illustrative and should not be used for actual construction without consulting the specific codes applicable to your project’s location and conditions. Always consult the official building code and manufacturer’s data for precise requirements.

| Scenario | Span Length (ft) | Load Type | Minimum Joist Hanger Load Capacity (lbs) | Fastener Requirements |

|---|---|---|---|---|

| Interior Partition | 8 | Live Load | 500 | Minimum 10d nails or equivalent |

| Exterior Wall | 10 | Dead Load + Live Load | 750 | Minimum 16d nails or equivalent |

| Floor Joist (High Load) | 12 | Dead Load + Live Load | 1000 | Minimum 16d nails and additional support |

Material Selection and Durability

Selecting the right material for 2×6 joist hangers is crucial for ensuring the long-term structural integrity and safety of a building. The choice depends on factors such as the load-bearing requirements, the environmental conditions of the construction site, and the desired lifespan of the structure. Different materials offer varying degrees of strength, corrosion resistance, and overall durability.

Joist Hanger Materials and Their Properties

Several materials are commonly used in the manufacturing of joist hangers, each possessing unique advantages and disadvantages. Galvanized steel, stainless steel, and sometimes even treated lumber are employed, each impacting the hanger’s performance and longevity. The selection process requires careful consideration of these material properties.

| Material | Advantages | Disadvantages |

|---|---|---|

| Galvanized Steel | Cost-effective, readily available, good strength-to-weight ratio, provides decent corrosion resistance due to zinc coating. | Susceptible to corrosion over time, especially in harsh environments with high humidity or salt exposure. Zinc coating can be scratched or damaged during installation, compromising its protective layer. |

| Stainless Steel | Excellent corrosion resistance, high strength, long lifespan, suitable for aggressive environments. | Higher cost compared to galvanized steel, potentially more difficult to work with. |

| Other Materials (e.g., Engineered Wood) | May offer design flexibility in certain applications, potentially lighter weight. | Generally lower strength and load capacity compared to steel options, more susceptible to moisture damage and degradation. Limited applications for joist hangers. |

Environmental Impact on Joist Hanger Longevity

Environmental factors significantly influence the durability and performance of joist hangers. Exposure to moisture, extreme temperatures, and UV radiation can accelerate material degradation and reduce the lifespan of the hangers. High humidity promotes corrosion in steel hangers, while freezing and thawing cycles can lead to cracking and weakening, particularly in less durable materials. Prolonged exposure to sunlight can also degrade the protective coatings on galvanized steel hangers. Proper ventilation and protection from the elements are essential for extending the lifespan of joist hangers.

Durability Comparison: Galvanized Steel vs. Stainless Steel

Direct comparison reveals stainless steel’s superior durability compared to galvanized steel, especially in challenging environments. While galvanized steel offers adequate protection in many applications, its zinc coating is not impervious to corrosion. Stainless steel, with its inherent corrosion resistance, provides a significantly longer lifespan, minimizing maintenance and replacement costs over time. For projects in coastal areas or environments with high humidity, stainless steel is the preferred choice to ensure long-term performance and structural integrity. The higher initial cost of stainless steel is often offset by its extended service life and reduced maintenance requirements.

Joist Hanger Material Selection Flowchart

The following flowchart illustrates a simplified decision-making process for selecting appropriate 2×6 joist hanger materials based on environmental conditions and performance requirements:

[Illustrative Flowchart Description: The flowchart would begin with a decision point: “Is the environment highly corrosive (coastal, high humidity)?”. A “Yes” branch would lead to “Select Stainless Steel Joist Hangers”. A “No” branch would lead to another decision point: “Is cost a primary concern?”. A “Yes” branch would lead to “Select Galvanized Steel Joist Hangers”. A “No” branch would lead to “Select Stainless Steel Joist Hangers” (prioritizing longevity over cost). This flowchart visually represents the material selection process, highlighting the crucial role of environmental considerations.]Troubleshooting Common Joist Hanger Issues

Proper installation of 2×6 joist hangers is crucial for the structural integrity of any building. Overlooking even minor details can lead to significant problems down the line, ranging from squeaking floors to more serious structural weaknesses. Understanding common issues and their solutions is essential for both professional contractors and DIY enthusiasts. This section details common problems encountered with 2×6 joist hangers, providing diagnostic methods and preventative measures.

Identifying and Resolving Common Joist Hanger Problems

Identifying problems early during installation or later during use is key to preventing costly repairs or structural damage. Careful inspection and a methodical approach to troubleshooting are crucial. Misaligned hangers, loose fasteners, and damaged hangers are among the most frequent issues.

Methods for Diagnosing and Resolving Joist Hanger Issues

Diagnosing joist hanger problems often involves a visual inspection, followed by a check for stability and load-bearing capacity. For example, a misaligned hanger might be visually apparent, while a loose fastener might require a more thorough examination, including checking for stripped threads or damaged wood. Solutions range from simple realignment and retightening to replacing damaged hangers entirely. Remember, safety is paramount; if unsure about a repair, consult a qualified structural engineer.

Preventative Measures for Minimizing Joist Hanger Problems

Prevention is always better than cure. Careful planning and meticulous installation are crucial in preventing common joist hanger problems. This includes using the correct hanger type for the load and lumber size, ensuring proper alignment before fastening, and using high-quality fasteners appropriately tightened. Regular inspections, especially in high-traffic areas, can help identify potential problems before they escalate.

Table of Common Joist Hanger Problems, Causes, and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Misaligned Joist Hanger | Improper placement of hanger on joist or beam; inaccurate measurement; uneven support surface. | Realign the hanger, ensuring proper seating on the joist and beam. Use shims if necessary to correct uneven surfaces. If significant misalignment is detected, replace the hanger. |

| Loose Fasteners | Inadequate tightening during installation; use of incorrect fasteners; wood splitting or damage. | Tighten loose fasteners. If fasteners are stripped or the wood is damaged, replace the hanger and use appropriate fasteners for the wood type. |

| Damaged Joist Hanger | Impact damage during construction; excessive load; corrosion (in certain materials). | Replace the damaged hanger. Ensure the replacement hanger is appropriate for the load and material. |

| Squeaking Joists | Loose hangers, movement of wood against metal, or insufficient support. | Tighten all fasteners; apply a lubricant (such as silicone spray) to reduce friction between the wood and metal. Consider adding additional support if necessary. |

| Sagging Joists | Overloading the joist system; use of incorrect hanger type; improper installation. | Assess the load on the joists and reinforce the system if necessary. Consult a structural engineer if the problem is severe. Ensure correct hanger type and installation method are followed. |

Mastering the art of 2×6 joist hanger installation is key to building strong and safe structures. This guide has equipped you with the knowledge to confidently select the appropriate hangers for your project, understand their load-bearing capabilities, and execute flawless installations. Remember, adherence to building codes and proper installation techniques are paramount to ensuring structural integrity and longevity. By understanding the nuances of 2×6 joist hangers, you can contribute to projects that are not only structurally sound but also built to last.

FAQ Section

What is the difference between galvanized and stainless steel joist hangers?

Galvanized steel offers good corrosion resistance at a lower cost, while stainless steel provides superior corrosion resistance, especially in harsh environments, but at a higher price point.

How often should I inspect my joist hangers?

Regular inspections, at least annually, are recommended, especially in areas prone to moisture or significant load changes. Look for signs of rust, damage, or loose fasteners.

Can I reuse joist hangers?

Generally, no. Once a joist hanger has been installed and loaded, it may be compromised and should be replaced. Reusing could significantly reduce its load-bearing capacity.

What happens if I use the wrong size joist hanger?

Using an incorrectly sized joist hanger can lead to structural failure. The hanger may not support the load, potentially causing collapse or significant damage.

Where can I find building code information specific to joist hangers?

Your local building department is the best resource for specific code requirements in your area. You can also consult the International Building Code (IBC) and relevant regional codes.