Board and batten siding installation offers a timeless and elegant aesthetic, transforming homes with its clean lines and rustic charm. This comprehensive guide delves into every aspect of the process, from initial planning and material selection to the final finishing touches. We’ll explore the different types of materials available, provide step-by-step instructions for installation, and offer solutions for common challenges. Whether you’re a seasoned DIY enthusiast or a first-time installer, this guide will equip you with the knowledge and confidence to successfully complete your board and batten siding project.

From understanding the nuances of various siding materials and their suitability to your project, to mastering the techniques of precise alignment and cutting, this guide leaves no stone unturned. We’ll cover essential preparatory steps, including site preparation and tool selection, ensuring a smooth and efficient installation process. We also address common pitfalls and offer practical solutions, making the entire project manageable and rewarding.

Understanding Board and Batten Siding: Board And Batten Siding Installation

Board and batten siding, a classic and enduring exterior cladding choice, offers a timeless appeal and remarkable durability. Its distinctive vertical lines create a clean, sophisticated look that complements a variety of architectural styles, from rustic farmhouses to modern coastal homes. This section delves into the characteristics, materials, and comparative advantages of board and batten siding, exploring its suitability for different aesthetic preferences.

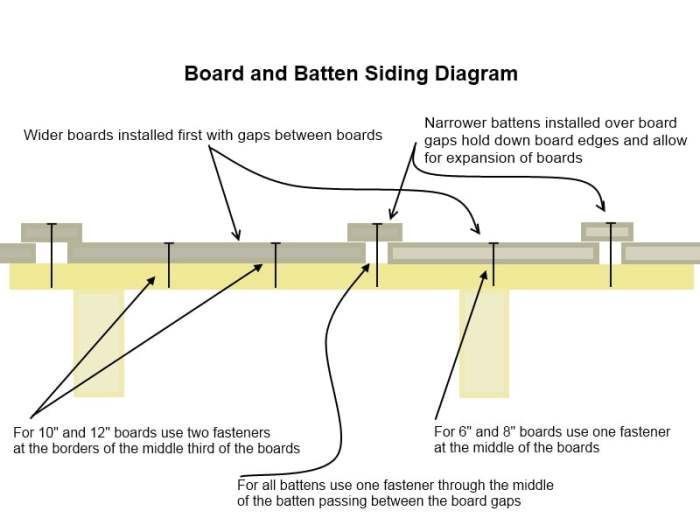

Board and batten siding is characterized by its simple yet elegant design. Wide vertical boards, known as battens, are installed and then narrower strips of wood, also called battens, are used to cover the seams between the wider boards, creating a clean, continuous vertical surface. This creates a visually appealing pattern that emphasizes vertical lines, adding visual height and interest to a building’s exterior. The overlapping nature of the battens contributes to its weather resistance, providing a protective barrier against the elements.

Board and Batten Siding Materials

The choice of material significantly impacts the longevity, maintenance requirements, and overall aesthetic of board and batten siding. Common materials include wood, fiber cement, and vinyl. Each offers unique advantages and disadvantages.

- Wood: Traditional and visually appealing, wood offers a natural, warm aesthetic. However, it requires regular maintenance, including painting or staining, to protect against rot, insect damage, and weathering. Popular wood choices include cedar, redwood, and pine, each offering varying levels of durability and resistance to the elements.

- Fiber Cement: A durable and low-maintenance alternative to wood, fiber cement siding mimics the look of wood but offers superior resistance to moisture, insects, and fire. It requires less maintenance than wood, but it is more expensive upfront.

- Vinyl: Vinyl board and batten siding is the most affordable option, offering low maintenance and a wide range of color choices. However, it is not as durable as wood or fiber cement and can be susceptible to damage from impact. Its appearance is often considered less natural compared to wood or fiber cement.

Board and Batten Siding Compared to Other Siding Options

Board and batten siding stands apart from other siding options due to its unique aesthetic and installation method. Compared to lap siding (which overlaps horizontally), board and batten offers a more modern and less busy appearance. While it may be more expensive than vinyl siding, it provides a more premium and longer-lasting finish. Compared to brick or stone, board and batten offers a more cost-effective alternative while still achieving a classic, elegant look. The choice ultimately depends on budget, maintenance preferences, and desired aesthetic.

Aesthetic Appeal and Architectural Styles

The clean lines and vertical orientation of board and batten siding lend themselves well to a variety of architectural styles. Its rustic charm complements farmhouse and traditional designs, while its clean lines can also enhance contemporary and modern homes. The material choice further influences the overall aesthetic; for instance, wood creates a warmer, more rustic feel, while fiber cement offers a more sleek, modern look. The color palette also plays a crucial role in shaping the overall aesthetic, with earthy tones commonly used to enhance the rustic appeal and brighter colors used to create a more contemporary feel. Examples include a white board and batten siding on a Cape Cod style home or a dark gray fiber cement board and batten on a modern minimalist home.

Planning and Preparation for Installation

Successful board and batten siding installation hinges on meticulous planning and preparation. Failing to adequately prepare can lead to costly mistakes, material waste, and a subpar final product. This section details the crucial steps involved in ensuring a smooth and efficient installation process.

Proper planning encompasses several key areas: designing a detailed installation plan, compiling a comprehensive list of necessary tools and materials, performing accurate site preparation and measurements, and establishing a waste management strategy to maintain a clean and organized workspace. Each of these aspects contributes significantly to the overall success of the project.

Step-by-Step Installation Plan

A well-defined installation plan is essential for efficient project execution. This plan should Artikel the sequence of tasks, from initial measurements and material preparation to the final finishing touches. Consider breaking down the project into manageable phases to facilitate progress tracking and resource allocation.

- Site Preparation and Measurements: Thoroughly clear the area, removing any obstacles that could impede the installation process. Precisely measure the area to be sided, accounting for all openings, corners, and irregularities.

- Material Preparation: Accurately cut all siding boards and battens to the required lengths, ensuring consistent sizing for a uniform appearance. Pre-treating the wood with a protective sealant or stain is also recommended at this stage.

- Sheathing Installation (if necessary): If installing over existing siding, ensure it’s in good condition. If installing directly onto studs, install appropriate sheathing and building wrap to provide a weather-resistant barrier.

- Installation of Starter Board: Install the starter board along the bottom of the wall, providing a level base for the remaining siding.

- Board and Batten Installation: Install vertical boards, ensuring proper spacing and alignment. Attach battens over the seams, creating the characteristic board and batten look. Work from bottom to top, ensuring each board is level and securely fastened.

- Finishing Touches: Caulk all gaps and seams to create a weathertight seal. Add trim and finishing details as needed to complete the installation.

Necessary Tools and Materials

Having all the necessary tools and materials readily available before starting the project will streamline the process and prevent delays. This list provides a comprehensive overview, but specific needs may vary depending on project size and complexity.

- Measuring tape

- Level

- Circular saw or miter saw

- Drill with various drill bits

- Hammer

- Nail gun (recommended)

- Caulk gun

- Safety glasses

- Work gloves

- Board and batten siding

- Nails or screws

- Caulk

- Trim (optional)

- Wood sealant or stain (optional)

Site Preparation and Measurements

Accurate site preparation and measurements are paramount to a successful installation. Inaccurate measurements can lead to material waste and a misaligned final product. Thorough preparation ensures a smooth and efficient installation process.

Begin by clearing the area of any debris or obstacles. Next, meticulously measure the area to be sided, taking into account all doors, windows, and other features. Consider using a laser level for precise measurements, especially on larger projects. Accurate measurements are crucial for ordering the correct amount of materials and preventing costly mistakes.

Waste Management and Worksite Cleanliness

Maintaining a clean and organized worksite is crucial for safety and efficiency. Implementing a waste management strategy minimizes environmental impact and ensures a professional finish. This involves careful planning for material disposal and regular cleanup throughout the project.

Consider using designated areas for different types of waste, such as scrap wood, packaging, and debris. Properly dispose of all waste according to local regulations. Regularly sweep and clean the work area to prevent accidents and maintain a safe working environment. For example, a large project might benefit from renting a dumpster for efficient waste removal.

Installation Process

Proper framing and sheathing are crucial for a successful board and batten siding installation. These steps create a strong, weather-resistant foundation that ensures the longevity and aesthetic appeal of your finished siding. Neglecting these foundational steps can lead to problems like water damage, structural weakness, and an uneven final appearance.

This section details the process of installing sheathing, framing around openings, and applying a weather barrier to prepare your walls for board and batten siding.

Sheathing Installation

Sheathing provides structural support and a continuous surface for the siding. Common sheathing materials include plywood, OSB (oriented strand board), and fiber cement. The choice depends on factors like budget, climate, and local building codes. Regardless of the material, proper installation is key. Sheathing should be installed horizontally, overlapping edges by a minimum of 1/4 inch to create a tight, continuous plane. All sheathing panels should be securely fastened with nails or screws, following the manufacturer’s recommended spacing and penetration depth. Ensure that fasteners are driven straight to avoid splitting the sheathing. Additionally, proper alignment of the sheathing is crucial for a smooth, even surface for the siding. Any gaps or unevenness will be reflected in the final appearance of the siding.

Framing Around Windows and Doors

Framing around windows and doors requires careful attention to detail to ensure proper flashing and a weathertight seal. Start by installing a continuous layer of flashing around the window or door frame, extending it several inches beyond the frame on all sides. This flashing will prevent water from penetrating behind the siding. Next, frame the opening using pressure-treated lumber to provide additional protection against moisture. Ensure the framing is plumb and square, creating a solid base for the siding. The framing should extend slightly beyond the window or door frame to provide a nailing surface for the siding. Accurate measurements and precise cuts are crucial to avoid gaps or inconsistencies that could compromise the weather resistance of the installation. Properly installed flashing and framing will prevent water intrusion and ensure a long-lasting, aesthetically pleasing installation.

House Wrap Installation

A house wrap, such as Tyvek or similar material, acts as a secondary weather barrier, preventing water penetration while allowing moisture vapor to escape from within the wall cavity. It should be installed over the sheathing, overlapping seams by a minimum of 6 inches, and secured with staples or nails. Pay particular attention to sealing all seams and corners with house wrap tape to create a continuous barrier. The house wrap should be installed taut to prevent sagging or wrinkles that could compromise its effectiveness. Correctly installed house wrap significantly enhances the weather resistance of the wall assembly and helps to protect the underlying structure and insulation. Furthermore, a properly installed house wrap contributes to a more energy-efficient building envelope, reducing heating and cooling costs.

Preparing the Wall Surface

Before siding installation, the wall surface needs to be thoroughly inspected and prepared. This involves removing any debris, loose materials, or protruding nails. Any damaged areas of the sheathing or framing should be repaired or replaced. Ensure the surface is clean and dry before proceeding to the next step. A smooth, even surface is essential for a professional-looking siding installation. This preparatory step is often overlooked, but it’s crucial for a successful outcome. Taking the time to thoroughly prepare the wall surface will save time and effort later in the process and result in a higher-quality installation.

Installation Process

With the planning and preparation complete, the actual installation of board and batten siding can begin. This process involves meticulous attention to detail to ensure a visually appealing and structurally sound finish. Proper installation techniques are crucial for maximizing the lifespan and weather resistance of your siding.

Vertical Batten Installation, Board and batten siding installation

Begin by installing the vertical battens, which serve as a framework for the horizontal boards. These battens should be plumb and spaced according to your design plan. Typically, 1×4 or 1×6 lumber is used for battens. Secure the battens to the wall framing using appropriate fasteners, ensuring they are level and straight. Use a level and a plumb bob to check for accuracy frequently throughout the installation process. Pre-drilling pilot holes will prevent splitting the wood, especially with harder woods. Spacing between battens will dictate the width of the horizontal boards. Consistent spacing is key for a professional finish.

Horizontal Board Attachment

Once the battens are securely in place, the horizontal boards can be installed. Start at the bottom and work your way up, ensuring each board is level and aligned with the battens. Use exterior-grade nails or screws, driving them at a slight angle to prevent the boards from lifting over time. Maintain consistent spacing between the boards, ensuring that the gaps are uniform across the entire surface. The exact spacing will depend on your design and the width of your chosen boards. Overlapping boards are not necessary in a board and batten installation; each board should butt against the next.

Achieving Precise Alignment and Spacing

Maintaining precise alignment and spacing is paramount for a professional-looking finish. Use a chalk line to mark the top and bottom edges of each batten before installation. This will ensure the battens are straight and evenly spaced. For consistent spacing between boards, use spacers. These can be simple pieces of wood or commercially available spacers designed for siding installation. Regularly check your work with a level and measuring tape to ensure accuracy. Slight imperfections can be corrected as you go, but large discrepancies may require removal and reinstallation.

Cutting and Fitting Around Corners and Obstacles

Installing siding around corners and obstacles requires careful measurement and precise cutting. Use a miter saw for clean, accurate cuts. For inside corners, miter the ends of the boards at a 45-degree angle and fit them together tightly. For outside corners, you can use a similar approach, or utilize pre-fabricated corner pieces for a neater finish. When encountering windows or doors, measure carefully and cut the boards to fit snugly around the frames. Consider using trim pieces to create a finished look around these features.

Fastening Methods

| Fastener Type | Application | Advantages | Disadvantages |

|---|---|---|---|

| Exterior-grade nails | General siding installation | Cost-effective, readily available | Can be prone to loosening over time, potential for splitting |

| Exterior-grade screws | Areas requiring extra strength, wider boards | Stronger hold, less prone to loosening | More expensive, slower installation |

| Galvanized nails | High-moisture environments | Rust resistant | Can be brittle |

| Stainless steel screws | Premium applications, coastal areas | Superior corrosion resistance, strong hold | Most expensive |

Finishing Touches and Caulking

The final stages of board and batten siding installation involve meticulous attention to detail, ensuring both aesthetic appeal and long-term weather protection. Proper caulking and sealing are critical to prevent water intrusion and maintain the integrity of the siding. A well-applied finish coat of paint or stain will enhance the beauty and longevity of your investment.

Caulking effectively seals gaps and joints, preventing water damage and air leakage. This crucial step protects the underlying structure from the elements, contributing significantly to the overall durability and energy efficiency of your home. Neglecting proper caulking can lead to costly repairs down the line, including rot, mold, and structural damage. Therefore, choosing the right caulk and applying it correctly is paramount.

Caulking Techniques and Material Selection

Choosing the right caulking material is vital for successful sealing. Exterior-grade acrylic latex caulk is a popular choice for its flexibility, paintability, and ease of application. It provides a durable seal that can withstand temperature fluctuations and exposure to the elements. Silicone caulk, while more durable, is less paintable and can be more challenging to work with. For gaps larger than ¼ inch, backer rod should be used to fill the space before applying caulk, ensuring efficient material use and preventing excessive caulk shrinkage. Apply caulk smoothly using a caulking gun, ensuring complete coverage of the joint. Tool the caulk immediately with a wet finger or a caulking tool to create a smooth, even finish.

Applying Paint or Stain

Once the caulking is complete and thoroughly dry, the next step is applying the chosen finish. Whether you opt for paint or stain depends on personal preference and the desired aesthetic. Paint offers a durable, opaque finish that provides excellent protection against the elements. Stain, on the other hand, allows the natural wood grain to show through, creating a more rustic and natural look. Regardless of your choice, ensure the surface is clean and dry before applying the first coat. Use high-quality exterior paint or stain formulated to withstand harsh weather conditions. Apply multiple thin coats, allowing each coat to dry completely before applying the next, for optimal coverage and durability. Follow the manufacturer’s instructions for drying times and recoating intervals.

Maintaining Board and Batten Siding

Regular maintenance is essential for preserving the appearance and longevity of your board and batten siding. Annually inspect the siding for any signs of damage, such as cracks, loose boards, or peeling paint. Address any issues promptly to prevent further deterioration. Clean the siding regularly to remove dirt, debris, and mildew. A pressure washer can be used, but caution is advised to avoid damaging the wood. For stubborn stains or mildew, use a suitable cleaning solution following the manufacturer’s instructions. Repainting or restaining every few years, depending on the climate and the type of finish used, will help maintain the siding’s protective layer and its aesthetic appeal. This proactive approach will ensure your board and batten siding remains beautiful and functional for years to come.

Addressing Common Installation Challenges

Board and batten siding installation, while achievable for DIYers, presents several potential challenges. Understanding these common problems and their solutions is crucial for a successful and aesthetically pleasing outcome. Proper planning and meticulous execution are key to mitigating these issues and achieving a professional-looking finish.

Uneven Surfaces and Difficult Angles

Uneven surfaces and difficult angles are frequently encountered during board and batten installation. These irregularities can significantly impact the final appearance and structural integrity of the siding. Addressing these challenges requires careful planning and the use of appropriate techniques.

Dealing with Uneven Walls

Uneven walls present a significant challenge, requiring careful measurement and adjustments to ensure a consistent and visually appealing installation. Before installing the battens, it is essential to assess the wall’s irregularities. Significant deviations from a plumb and level surface may necessitate shimming or furring strips to create a consistent base for the siding. This ensures that the battens and boards are properly aligned and avoid any gaps or unevenness. Shimming involves placing small pieces of wood between the wall and the framing to create a level surface. Furring strips, which are thin strips of wood, can be nailed directly to the wall to create a new, level surface for the siding.

Managing Difficult Angles

Sharp angles, such as corners and around windows and doors, demand precision cutting and fitting. Accurate measurements are paramount. Pre-cutting boards and battens to fit these angles is recommended. Utilizing a miter saw with a fine-tooth blade ensures clean, precise cuts, minimizing gaps and maximizing the aesthetic appeal. For particularly complex angles, using a combination of mitered and butt joints may be necessary, requiring careful attention to alignment and sealing to prevent water penetration.

Troubleshooting Common Installation Issues

Improper planning and execution can lead to several common issues. Addressing these promptly is vital to avoid costly repairs and ensure the longevity of the siding.

Warping and Splitting of Boards

Warping and splitting of boards are common problems stemming from improper storage, handling, or the use of low-quality materials. Always choose high-quality, properly seasoned wood. Acclimation of the wood to the environment before installation is also crucial. Storing the boards horizontally in a dry, well-ventilated area prevents warping. Inspect boards for defects before installation; reject any exhibiting significant warping or splitting. If splitting occurs during installation, carefully assess the damage. Minor splits can be filled with wood filler, while significant splits may require replacing the board.

Gaps and Misalignments

Gaps and misalignments between boards and battens are often caused by inaccurate measurements or improper nailing techniques. Consistent use of a level during installation helps maintain alignment. Use appropriately sized nails, ensuring they are driven straight and deep enough to secure the boards without causing damage. For larger gaps, use wood shims to create a consistent surface before nailing. Gaps can also be addressed using exterior-grade caulk to seal the joints and prevent water intrusion.

Nail Pops

Nail pops occur when nails back out of the wood, creating unsightly protrusions. This often happens due to improper nailing, using nails that are too short, or wood movement. To prevent nail pops, use exterior-grade nails of appropriate length, driven straight and deep enough to secure the boards firmly. Countersinking nails slightly below the surface and filling the holes with wood filler can also minimize the appearance of nail pops. If nail pops occur, carefully remove the nail, add a small amount of wood glue, and reinstall the nail, ensuring it is properly set.

Illustrative Examples

Visual representations are crucial for understanding the nuances of board and batten siding installation. The following examples illustrate both a straightforward installation and a more complex scenario, highlighting best practices and problem-solving techniques.

Properly installed board and batten siding showcases clean lines and a professional finish. Understanding these examples helps homeowners and contractors alike achieve similar results.

Proper Board and Batten Installation

Imagine a section of a wall, approximately 8 feet wide and 6 feet high, clad in board and batten siding. The vertical battens, 1×4 inch pine, are evenly spaced at 12 inches on center. These battens are primed and painted a deep charcoal grey, creating a strong visual contrast. Between the battens are horizontal boards, 1×6 inch pine, also primed and painted the same grey. The boards are neatly butted together, with no visible gaps. Each board is carefully nailed to the battens using galvanized nails, countersunk and filled with wood filler for a smooth surface. The wood grain is oriented consistently throughout the installation, creating a visually unified aesthetic. The entire section demonstrates precise cuts and a clean, professional finish. The corners are mitered for a seamless appearance. The overall effect is one of classic, understated elegance, showcasing the potential of board and batten siding to enhance curb appeal.

Challenging Installation Scenario: Corner Window

This example depicts a more complex installation scenario involving a corner window. The window is recessed approximately 6 inches into the wall, with the frame extending outwards. The challenge lies in seamlessly integrating the board and batten siding around the window frame while maintaining the consistent aesthetic of the rest of the wall. The solution involves carefully measuring and cutting the boards and battens to fit precisely around the window’s protruding frame. The battens are cut at angles to precisely meet at the window’s corners. The horizontal boards are similarly cut and fitted, ensuring a tight fit without gaps or unsightly overlaps. To further refine the installation, small trim pieces are used to cover any exposed edges of the window frame, ensuring a seamless transition between the siding and the window. The corner boards are meticulously mitered, ensuring a sharp, clean intersection. The use of high-quality caulk ensures a weather-tight seal around the window frame, preventing water intrusion. The final result demonstrates the skill and precision required to overcome the complexities of a challenging installation, resulting in a professional and visually appealing finish that complements the window’s design.

Mastering board and batten siding installation is a rewarding experience that adds undeniable curb appeal and lasting value to your home. By following the detailed steps Artikeld in this guide, and paying close attention to detail, you can achieve a professional-looking finish that you’ll be proud of for years to come. Remember that proper planning, careful execution, and attention to finishing touches are key to a successful project. So, gather your tools, embrace the process, and transform your home’s exterior with the enduring beauty of board and batten siding.

Question Bank

What is the lifespan of board and batten siding?

With proper installation and maintenance, board and batten siding can last for 30-50 years or more, depending on the material used and environmental conditions.

Can I install board and batten siding over existing siding?

In some cases, yes, but it depends on the condition of the existing siding. Proper assessment is crucial; sometimes removal of the old siding is necessary for a successful installation.

How much does board and batten siding installation cost?

The cost varies significantly based on factors such as material choice, labor costs, and project size. Getting multiple quotes from reputable contractors is recommended.

What type of paint or stain is best for board and batten siding?

Exterior-grade paints and stains designed for wood are best. Consider factors like UV resistance and weather protection when selecting your finish.

How do I clean board and batten siding?

Regular cleaning with a pressure washer (low pressure setting) and a mild detergent solution will keep your siding looking its best. Avoid harsh chemicals.