Composite shake siding offers a compelling alternative to traditional wood shakes, boasting durability, low maintenance, and aesthetic appeal. This comprehensive guide delves into the manufacturing process, material composition, and installation techniques of composite shake siding, comparing it to wood and vinyl alternatives. We’ll explore its advantages, costs, environmental impact, and troubleshooting common issues, equipping you with the knowledge to make an informed decision.

From understanding the various styles and colors available to navigating warranty information and long-term cost-effectiveness, this guide provides a complete overview of composite shake siding, helping homeowners and contractors alike. We’ll cover everything from choosing the right color to complement your home’s style to understanding the nuances of installation and maintenance, ensuring a successful project from start to finish.

Introduction to Composite Shake Siding

Composite shake siding offers a durable and attractive alternative to traditional wood shake, providing homeowners with a low-maintenance, aesthetically pleasing exterior. This material combines the visual appeal of natural wood with enhanced performance characteristics, making it a popular choice for both new construction and renovations. Understanding its manufacturing process and material composition is key to appreciating its benefits.

Composite shake siding manufacturing involves a process of combining various materials to create a product that mimics the look and texture of natural wood shakes. The process typically begins with the selection and preparation of raw materials, followed by mixing, molding, and curing. Finally, the finished product undergoes quality control checks before packaging and distribution. Specific processes may vary depending on the manufacturer and the desired product characteristics.

Composite Shake Siding Materials

The composition of composite shake siding varies depending on the manufacturer, but generally includes a blend of materials designed to enhance durability, weather resistance, and aesthetic appeal. Common components include wood fibers or other cellulose-based materials, polymers such as polyethylene or PVC, and various additives to improve properties like color stability, UV resistance, and fire retardancy. The precise ratios of these components are proprietary information for most manufacturers, contributing to the variation in performance and cost among different brands. These materials are carefully combined to create a composite material that is both strong and lightweight.

Composite Shake Siding vs. Traditional Wood Shake Siding

Composite and wood shake sidings both offer a visually appealing, textured exterior, but their performance characteristics differ significantly. Wood shake siding, while aesthetically pleasing, is susceptible to rot, insect infestation, and requires regular maintenance, including staining and sealing, to extend its lifespan. It is also more flammable than composite alternatives. In contrast, composite shake siding offers superior resistance to rot, insects, and fire. It typically requires minimal maintenance, reducing long-term costs associated with upkeep. While the initial cost of composite siding may be higher than wood, the reduced maintenance and extended lifespan often make it a more cost-effective option in the long run. The lower maintenance requirements also translate to less disruption for homeowners.

Advantages of Composite Shake Siding

Composite shake siding offers a compelling alternative to traditional wood and vinyl siding, boasting a blend of aesthetics and practicality that appeals to homeowners seeking a durable and low-maintenance exterior. Its realistic wood-shake appearance provides the charm of natural materials without the associated drawbacks. This section details the key benefits of choosing composite shake siding.

Low Maintenance Requirements

Composite shake siding significantly reduces the upkeep associated with exterior home maintenance. Unlike wood siding, which requires regular staining, painting, and sealing to prevent rot, insect infestation, and weathering, composite materials are designed for resilience. This inherent resistance to moisture, rot, and insect damage translates to less frequent cleaning and fewer repairs over the siding’s lifespan. A simple occasional washing with water and a mild detergent is often sufficient to maintain its appearance. This translates to significant cost savings over time, both in terms of materials and labor.

Durability and Longevity Across Diverse Climates

Composite shake siding is engineered to withstand harsh weather conditions, demonstrating superior durability compared to wood or vinyl alternatives. Its resistance to fading, cracking, and warping ensures a consistently attractive appearance, regardless of exposure to intense sunlight, freezing temperatures, or high humidity. For example, in coastal regions prone to salt spray, composite siding’s resistance to moisture damage makes it a far more suitable choice than wood, which is susceptible to rapid deterioration in such environments. Similarly, in areas with extreme temperature fluctuations, composite siding’s resistance to expansion and contraction minimizes the risk of cracking and warping, preserving its structural integrity and aesthetic appeal.

Resistance to Pests and Insects

Wood shake siding is notoriously vulnerable to insect infestation, requiring regular treatment and potentially costly repairs. Composite materials, however, are inherently resistant to termites, carpenter ants, and other wood-boring insects. This inherent pest resistance eliminates the need for ongoing pest control measures, saving both time and money in the long run. This feature is particularly advantageous in regions where insect infestations are prevalent.

Fire Resistance

Composite shake siding often incorporates fire-retardant properties, offering superior protection compared to wood siding. This enhanced fire resistance contributes to increased home safety, minimizing the risk of fire spread in the event of an external fire. Many composite siding products meet or exceed building codes for fire safety, providing homeowners with an added layer of security.

Variety of Styles and Colors

Composite shake siding offers a wide array of styles and colors to complement various architectural designs. The realistic texture and appearance of natural wood shakes are faithfully replicated, allowing homeowners to achieve the desired aesthetic without compromising on the benefits of composite materials. This versatility ensures that homeowners can find a style and color that perfectly matches their home’s architecture and personal preferences.

Lifespan Comparison of Siding Materials

| Siding Material | Estimated Lifespan (Years) | Maintenance Requirements | Cost Considerations |

|---|---|---|---|

| Composite Shake Siding | 30-50+ | Low; occasional cleaning | Higher initial cost, lower long-term cost |

| Wood Shake Siding | 15-30 | High; regular staining, sealing, and potential repairs | Lower initial cost, higher long-term cost |

| Vinyl Siding | 20-30 | Moderate; occasional cleaning | Moderate initial and long-term cost |

Installation and Maintenance of Composite Shake Siding

Composite shake siding offers a durable and attractive alternative to traditional wood shakes, but proper installation and maintenance are crucial for maximizing its lifespan and aesthetic appeal. This section details the step-by-step process of installation and provides essential maintenance tips to keep your siding looking its best for years to come.

Composite Shake Siding Installation

Installing composite shake siding involves several key steps, requiring careful attention to detail for a professional finish. Improper installation can lead to issues such as water damage and premature wear. The process generally begins with preparation and continues through the installation of the siding itself. Always refer to the manufacturer’s specific instructions for your chosen product.

- Preparation: Before beginning, ensure the underlying wall sheathing is properly prepared. This includes repairing any damaged areas, ensuring a level surface, and installing appropriate flashing around windows and doors to prevent water penetration. All necessary tools should be gathered, including a measuring tape, circular saw, nail gun, safety glasses, and work gloves.

- Starter Strip Installation: Install a starter strip along the bottom edge of the wall. This provides a straight, level base for the first course of siding and helps maintain consistent spacing throughout the installation. The starter strip is typically nailed securely to the sheathing.

- Siding Installation: Begin installing the composite shake siding from the bottom up, overlapping each course according to the manufacturer’s specifications. Use galvanized nails or appropriate fasteners to secure the siding to the wall sheathing. Maintain consistent spacing and alignment throughout the installation process. A nail gun significantly speeds up the process and ensures consistent penetration.

- Cutting and Fitting: For corners and around windows and doors, you’ll need to cut the siding to fit. Use a sharp circular saw to make precise cuts. Take extra care to ensure a tight, weather-resistant seal around openings. Properly sealing these areas is critical to preventing water damage.

- Finishing: Once all the siding is installed, inspect the work for any gaps or inconsistencies. Caulk any gaps to ensure a weather-tight seal. Consider adding trim pieces for a more finished look. A thorough final inspection ensures a professional and durable installation.

Maintaining and Cleaning Composite Shake Siding

Regular cleaning and maintenance are essential for preserving the beauty and longevity of your composite shake siding. Neglecting maintenance can lead to the accumulation of dirt, grime, and mildew, potentially compromising the siding’s appearance and structural integrity.

- Regular Cleaning: Use a garden hose with a nozzle to rinse away loose dirt and debris. For more stubborn stains, use a mild detergent solution and a soft-bristled brush. Avoid using harsh chemicals or abrasive cleaners, as these can damage the siding’s surface.

- Mildew Removal: Mildew can appear as dark spots or streaks on the siding. Treat mildew with a solution of bleach and water (following the manufacturer’s recommendations for your specific siding), applying it with a soft brush. Rinse thoroughly afterward. Regular cleaning helps prevent mildew growth.

- Annual Inspection: Perform a thorough inspection of your siding at least once a year, checking for any signs of damage, such as cracks, loose pieces, or water damage. Address any issues promptly to prevent further problems. Early detection of issues is crucial for effective and timely repairs.

Cost and Value of Composite Shake Siding

Choosing the right siding for your home involves careful consideration of both upfront costs and long-term value. Composite shake siding presents a compelling option, but understanding its cost implications relative to other materials and its impact on your home’s value is crucial for informed decision-making. This section will analyze the initial investment, ongoing maintenance expenses, and the overall return on investment associated with composite shake siding.

Composite shake siding typically commands a higher initial cost compared to traditional vinyl or fiber cement siding. However, this higher upfront investment is often offset by its superior durability and lower maintenance requirements over its lifespan. A direct price comparison against alternatives like wood shake, which requires significant and frequent maintenance, highlights the long-term cost-effectiveness of composite. For example, a 2,000 square foot home might see an initial cost difference of several thousand dollars between composite shake and vinyl siding. However, factoring in the cost of repainting, repairing, and potentially replacing wood shake every 10-15 years, the composite option often proves more economical in the long run.

Initial Cost Comparison with Other Siding Options

The initial cost of composite shake siding varies based on factors such as the chosen manufacturer, the complexity of the installation (including the need for specialized trims or underlayment), and regional labor costs. Generally, it falls within a higher price bracket than vinyl siding but often costs less than real wood shake or certain high-end fiber cement options. A reliable contractor can provide a detailed breakdown of material and labor costs specific to your project, enabling a direct comparison with alternative siding choices. This allows for a comprehensive evaluation of the immediate financial commitment required for each option. For instance, while vinyl might be significantly cheaper upfront, the potential for earlier replacement due to weathering or damage could negate those initial savings over the long term.

Long-Term Cost-Effectiveness Considering Maintenance and Replacement

Composite shake siding’s low-maintenance nature contributes significantly to its long-term cost-effectiveness. Unlike wood shake, which requires regular staining, sealing, and potential repairs due to rot, insect damage, or weathering, composite shake is resistant to these issues. This significantly reduces ongoing maintenance expenses. The material’s inherent durability means it often requires less frequent cleaning and repairs, leading to substantial savings over decades compared to higher-maintenance alternatives. For instance, eliminating the need for periodic repainting alone can save homeowners hundreds or even thousands of dollars over the lifespan of the siding. This translates to lower overall lifetime costs despite the higher initial investment.

Impact of Composite Shake Siding on Home Value

The investment in composite shake siding can positively impact your home’s value. Its attractive appearance, durability, and low-maintenance nature are all factors that appeal to potential buyers. The enhanced curb appeal provided by high-quality siding can make a significant difference in a home’s market value. Real estate professionals often note that energy-efficient features and attractive exterior finishes, such as composite shake siding, are increasingly sought-after by buyers, leading to higher sale prices. For example, a recent appraisal might show a higher value for a home with composite shake siding compared to a similar home with less durable and less aesthetically pleasing siding, reflecting the material’s contribution to the property’s overall desirability and market value.

Styles and Colors of Composite Shake Siding

Composite shake siding offers a remarkable range of styles and colors, allowing homeowners to achieve a wide variety of aesthetic looks for their homes, from rustic charm to modern elegance. The versatility of this material allows for seamless integration with various architectural styles and personal preferences. Understanding the available options is key to making an informed decision that enhances the curb appeal and overall value of your property.

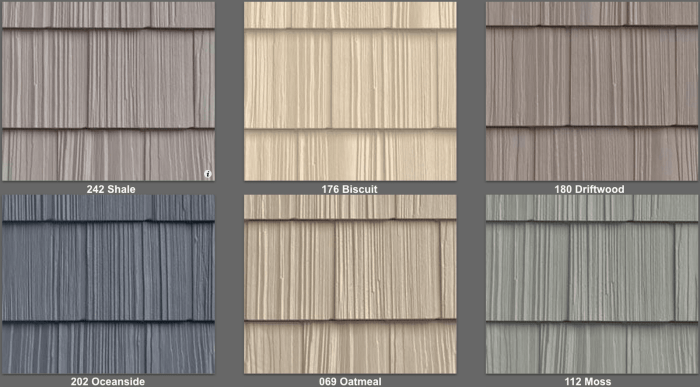

Composite shake siding mimics the appearance of natural cedar or wood shakes, but with enhanced durability and low-maintenance benefits. The manufacturing process allows for a variety of textures, replicating the subtle variations found in natural wood. These textures range from deeply grooved and rough-hewn looks to smoother, more refined profiles. Color choices are equally diverse, expanding beyond the traditional earthy tones to include bolder and more contemporary options. The color consistency of composite materials ensures a uniform appearance across the entire siding installation, unlike natural wood which can vary in shade over time.

Available Styles and Textures

Composite shake siding manufacturers offer a spectrum of styles designed to replicate the appearance of various natural wood shakes. These include options that emulate the deeply textured and rough-hewn look of hand-split shakes, providing a rustic and traditional aesthetic. Other styles mimic the more refined and uniform appearance of machine-cut shakes, offering a slightly more polished and modern feel. Some manufacturers even incorporate variations in thickness and depth within a single panel to further enhance the realism and visual interest. The textures themselves can range from a deeply embossed, almost three-dimensional appearance, to smoother, less pronounced textures that still maintain the overall shape and profile of a shake.

Color Options and Design Aesthetics

The color palette for composite shake siding is extensive, allowing homeowners to match their siding to their home’s architectural style and personal taste. Popular choices often reflect the natural world, with earthy tones such as browns, grays, and greens dominating the market. However, manufacturers also offer a wide array of more contemporary colors, including blacks, deep blues, and even reds. The choice of color can significantly impact the overall look and feel of a home.

For example, a home with a traditional design might be complemented by warm brown or gray tones, echoing the natural environment. These colors create a sense of warmth and familiarity. Conversely, a modern home might benefit from a bolder color choice such as charcoal gray or deep blue, providing a striking contrast and emphasizing clean lines. Homes with a craftsman style might be well-suited to lighter shades of gray or brown with subtle variations in color, mimicking the natural weathering of wood.

Below is a list of popular color options and their associated design aesthetics:

| Color | Design Aesthetic | Home Style Complement |

|---|---|---|

| Warm Brown | Rustic, Traditional | Colonial, Craftsman, Farmhouse |

| Gray | Modern, Classic | Contemporary, Ranch, Cape Cod |

| Charcoal Gray | Modern, Sophisticated | Modern, Minimalist |

| Deep Green | Earthy, Natural | Farmhouse, Rustic |

| Dark Brown | Elegant, Traditional | Victorian, Tudor |

Environmental Impact of Composite Shake Siding

Composite shake siding presents a complex environmental profile, balancing the benefits of reduced deforestation against the impacts of manufacturing and disposal. Understanding its lifecycle—from raw material extraction to end-of-life management—is crucial for evaluating its overall sustainability. This section examines the environmental considerations associated with composite shake siding, comparing it to traditional wood and vinyl alternatives.

The manufacturing process of composite shake siding involves the combination of various materials, typically recycled plastics and wood fibers, along with binders and pigments. Energy consumption during manufacturing is a significant factor, contributing to greenhouse gas emissions. The extraction and processing of raw materials also have environmental consequences, including potential habitat disruption and pollution from manufacturing plants. Disposal presents another challenge, as composite siding is not readily biodegradable. However, advancements in material composition and recycling technologies are continuously striving to mitigate these impacts.

Manufacturing Emissions and Energy Consumption

The energy intensity of composite shake siding manufacturing varies depending on the specific composition and manufacturing processes employed by different manufacturers. Generally, it requires less energy than the production of certain types of wood siding, particularly those requiring extensive transportation from distant sources. However, it often requires more energy than the production of vinyl siding, a material that typically involves simpler manufacturing processes. A life-cycle assessment (LCA) is the best method for comparing the overall energy consumption of various siding options, considering factors like transportation, material extraction, and manufacturing. For example, a comprehensive LCA might reveal that composite siding from a nearby manufacturer with a focus on renewable energy sources would have a lower carbon footprint than wood siding transported across the country.

Comparison with Wood and Vinyl Siding

Wood siding, while a natural material, carries a significant environmental footprint. Deforestation for timber harvesting contributes to habitat loss and biodiversity reduction. Furthermore, the transportation of lumber, particularly over long distances, adds to greenhouse gas emissions. The use of chemical treatments to protect wood siding from pests and decay also poses environmental risks. Vinyl siding, on the other hand, is derived from petroleum, a non-renewable resource. Its manufacturing process generates significant greenhouse gas emissions and often involves the use of harmful chemicals. The durability of vinyl siding means that its disposal presents a significant challenge. Composite shake siding, by utilizing recycled materials and reducing reliance on virgin timber, can offer a more environmentally balanced alternative in some instances, although a comprehensive LCA is necessary to confirm this for each specific product and situation.

Recyclability and Sustainability Aspects

The recyclability of composite shake siding varies depending on the specific materials used and the availability of recycling infrastructure. Some manufacturers are actively developing programs to reclaim and recycle their products, contributing to a more circular economy. However, widespread recycling programs for composite siding are still limited. The sustainability of composite shake siding is also enhanced by the use of recycled materials, reducing the demand for virgin resources. Furthermore, the durability and longevity of composite siding can contribute to its overall environmental performance, reducing the frequency of replacement and associated waste generation. However, the long-term effects of the degradation of composite materials in landfills require further investigation. Innovative solutions, such as using bio-based resins and improving the recyclability of composite materials, are essential to enhance the sustainability of this product category.

Troubleshooting Common Issues with Composite Shake Siding

Composite shake siding, while durable and low-maintenance, can still present some challenges. Understanding common problems and their solutions is crucial for maintaining the aesthetic appeal and longevity of your siding. This section Artikels typical issues, providing practical solutions and preventative measures to ensure your composite shake siding remains in top condition.

Water Damage and Moisture Intrusion

Water damage is a significant concern with any exterior siding. For composite shake siding, this can manifest as discoloration, warping, or even mold growth. Proper installation is key to preventing water intrusion. Ensure all seams are properly sealed, and that flashing is installed correctly around windows and doors. Regular inspections, particularly after heavy rainfall or snowmelt, can help identify and address leaks early. Addressing minor leaks promptly prevents larger, more costly repairs down the line. For example, a small gap between two pieces of siding can be easily sealed with a high-quality exterior-grade caulk. Larger areas of damage may require replacing affected sections.

Fading and Discoloration, Composite shake siding

Exposure to the elements, particularly UV radiation from sunlight, can cause composite shake siding to fade over time. The extent of fading depends on factors such as the siding’s color, the intensity of sunlight, and the presence of any protective coatings. Choosing a color with UV inhibitors can significantly reduce fading. Regular cleaning with a gentle detergent and water can also help remove dirt and grime that can contribute to discoloration. In cases of significant fading, repainting or restaining might be necessary, although this is less common with composite materials than with natural wood.

Damage from Impact

While more resistant to impact than some other siding materials, composite shake siding can still be damaged by strong impacts, such as hail or flying debris. Minor dents or scratches can often be repaired using a putty or filler specifically designed for composite materials. Larger impacts may require replacing damaged sections. Installing protective barriers, such as storm shutters, can help minimize the risk of impact damage, particularly in areas prone to severe weather.

Improper Installation Issues

Problems stemming from improper installation often manifest as gaps between siding pieces, leading to water intrusion or aesthetic imperfections. These issues are usually preventable with careful planning and execution during installation. A thorough understanding of the manufacturer’s instructions is paramount. For example, ensuring proper overlapping of siding pieces and using appropriate fasteners is crucial. If gaps appear after installation, they should be addressed immediately with appropriate caulking or sealant. Addressing these issues promptly can prevent costly repairs down the line.

Pest Infestation

Although composite shake siding is resistant to insect infestation, it is not entirely immune. Some insects might still find ways to nest or burrow near seams or damaged areas. Regular inspection can identify any signs of pest activity early. Addressing any potential entry points, such as gaps or cracks, can help prevent infestation. In case of an infestation, professional pest control may be necessary.

Warranty and Guarantees

Understanding the warranty and guarantees offered by composite shake siding manufacturers is crucial for making an informed purchase decision. These warranties protect your investment and provide recourse should issues arise with the product’s quality or performance. The specifics of these warranties vary considerably between manufacturers, so careful comparison is recommended.

Manufacturers typically offer warranties covering defects in materials and workmanship. The length of these warranties can range from 25 to 50 years, or even longer, depending on the manufacturer and specific product line. Some warranties cover only the original purchaser, while others may be transferable to subsequent homeowners. It’s important to read the warranty document carefully to understand the exact terms and conditions.

Warranty Coverage Details

Common warranty coverage includes defects in materials, such as fading, cracking, or delamination of the composite material. Workmanship defects, such as improper installation or manufacturing flaws, are also typically covered. However, warranties often exclude damage caused by external factors, such as severe weather events, improper maintenance, or vandalism. Exclusions may also include damage caused by normal wear and tear or issues arising from improper installation. Specifics regarding these exclusions vary widely among manufacturers.

Comparison of Manufacturer Warranty Offerings

A direct comparison of warranty offerings across various manufacturers requires accessing the specific warranty documents from each company. However, a general overview can be provided. Some manufacturers offer comprehensive, transferable, lifetime warranties covering a wide range of potential issues. Others may offer shorter-term warranties with more restrictive coverage. For example, Manufacturer A might offer a 30-year warranty covering material defects but only a 10-year warranty on labor, while Manufacturer B might offer a 50-year warranty covering both materials and workmanship, with the warranty transferable to future owners. Ultimately, prospective buyers should compare the specific terms and conditions provided in the warranty documents from each manufacturer to determine the best fit for their needs. Factors to consider include warranty length, coverage scope, transferability, and any exclusions.

Ultimately, the decision to use composite shake siding hinges on a careful consideration of your budget, aesthetic preferences, and long-term maintenance goals. While the initial cost may be higher than some alternatives, the durability, low maintenance, and potential increase in home value make it a strong contender. This guide has provided a detailed exploration of composite shake siding, arming you with the necessary information to make an informed choice that best suits your needs and enhances your property’s curb appeal for years to come.

FAQ Insights

Can composite shake siding be painted?

Yes, many composite shake siding products can be painted, but it’s crucial to use paints specifically designed for exterior use and follow the manufacturer’s recommendations.

How often should I clean my composite shake siding?

Regular cleaning, typically once or twice a year with a gentle pressure washer and mild detergent, will maintain its appearance and prevent the buildup of dirt and debris.

Does composite shake siding attract insects?

Unlike wood, composite shake siding is less susceptible to insect infestation, reducing the risk of damage and the need for pest control treatments.

What is the warranty typically offered on composite shake siding?

Warranties vary by manufacturer, but many offer a 25-30 year warranty covering defects in materials and workmanship. Always check the specific warranty details before purchasing.

Is composite shake siding fire resistant?

While not entirely fireproof, composite shake siding generally has a higher fire resistance rating than wood shake siding, offering a greater level of protection.