Fiber cement lap siding offers a compelling blend of durability, aesthetics, and low maintenance, making it a popular choice for homeowners seeking a long-lasting exterior solution. This comprehensive guide delves into the intricacies of fiber cement lap siding, exploring its composition, installation, maintenance, and cost-effectiveness compared to alternatives like vinyl and wood. We’ll examine various styles, textures, and colors, helping you make an informed decision for your home improvement project. From understanding the manufacturing process to mastering installation techniques and addressing common issues, we provide a complete overview to empower you with the knowledge you need.

This in-depth exploration covers everything from the historical evolution of fiber cement lap siding to its environmental impact, equipping you with a thorough understanding of this versatile building material. We’ll also examine the various types and styles available, providing practical advice on selecting the best option for your home’s architectural style and personal preferences. Whether you’re a seasoned DIY enthusiast or a homeowner seeking professional guidance, this guide serves as an invaluable resource.

Introduction to Fiber Cement Lap Siding

Fiber cement lap siding, a popular exterior cladding choice for its durability and aesthetic appeal, represents a significant advancement in building materials. Its robust construction and low-maintenance properties make it a compelling alternative to traditional wood siding and more contemporary vinyl options. This section delves into the manufacturing process, composition, advantages, and historical context of this versatile siding material.

Fiber Cement Lap Siding Manufacturing

The manufacturing process of fiber cement lap siding involves a precise blend of raw materials and sophisticated machinery. Portland cement, cellulose fibers (often from recycled paper), and silica sand are combined with water in a mixing process. This slurry is then formed into the desired shapes and thicknesses using high-pressure molding techniques. Subsequently, the formed panels undergo a curing process, typically involving steam curing under controlled temperature and pressure, to achieve the desired strength and durability. Finally, the cured panels are cut to size, sanded for a smooth finish, and often primed or pre-finished with a protective coating before being packaged and shipped for installation. The entire process ensures consistency in quality and dimensional accuracy across a wide range of product styles and colors.

Fiber Cement Lap Siding Composition and Ingredient Functions

Fiber cement lap siding is a composite material comprised primarily of three key ingredients: Portland cement, cellulose fibers, and silica sand. Portland cement acts as the binding agent, providing structural integrity and strength to the final product. Cellulose fibers, derived from recycled paper pulp, contribute to the overall tensile strength and flexibility of the siding, preventing cracking and brittleness. Silica sand, a naturally occurring mineral, enhances the durability and weather resistance of the siding, protecting it from moisture damage and UV degradation. Minor additives, such as pigments for color and other performance-enhancing chemicals, may also be included depending on the specific manufacturer and product specifications. The precise ratio of these ingredients determines the final properties of the siding, influencing its strength, flexibility, and resistance to weathering.

Advantages of Fiber Cement Lap Siding

Fiber cement lap siding offers a compelling array of advantages compared to other siding materials. Its superior durability and longevity are unmatched by vinyl siding, which is prone to cracking and fading under prolonged sun exposure. Unlike wood siding, fiber cement is inherently resistant to rot, insect infestation, and fire damage, requiring minimal maintenance and offering increased peace of mind. Moreover, fiber cement siding boasts excellent weather resistance, effectively withstanding harsh weather conditions, including extreme temperatures, heavy rain, and strong winds. The material’s versatility allows for a wide range of styles and finishes, mimicking the look of natural wood without the associated maintenance burdens. The overall cost-effectiveness of fiber cement siding, considering its long lifespan and reduced maintenance needs, further solidifies its position as a superior choice for many homeowners.

A Brief History of Fiber Cement Lap Siding

Fiber cement siding’s evolution in the building industry reflects a continuous drive for more durable and sustainable building materials. While the basic concept of using cement-based composites for construction dates back centuries, the development of modern fiber cement siding emerged in the mid-20th century as a response to the limitations of traditional wood siding. Early formulations focused primarily on functionality, prioritizing durability and fire resistance. Over time, advancements in manufacturing techniques and material science have led to improvements in aesthetic appeal, with a wider range of colors, textures, and profiles becoming available. Today, fiber cement siding is a mature and widely adopted building material, consistently gaining popularity due to its performance and longevity.

Types and Styles of Fiber Cement Lap Siding

Fiber cement lap siding offers a diverse range of options to suit various architectural styles and homeowner preferences. Understanding the different types and styles available is crucial for making informed decisions about material selection and overall project aesthetics. This section details the key characteristics of fiber cement lap siding, categorizing it by texture, color, and profile, and exploring installation methods and maintenance requirements.

Fiber Cement Lap Siding Categorization

The versatility of fiber cement lap siding is reflected in its wide array of textures, colors, and profiles. This table provides a concise overview of some common options.

| Texture | Color | Profile | Example |

|---|---|---|---|

| Smooth | Classic White | Standard 5-inch lap | A clean, minimalist look suitable for modern homes. |

| Wood Grain | Cedar Tone | Beaded lap | Mimics the appearance of natural cedar wood, adding a rustic charm. |

| Rough Sawn | Gray | 7-inch double lap | Offers a more textured, rustic appearance, ideal for farmhouse or craftsman styles. |

| Smooth | Dark Charcoal | Shadow line lap | Creates a sophisticated and contemporary look with deep shadow lines. |

Fiber Cement Lap Siding Installation Methods

The installation method for fiber cement lap siding varies depending on the chosen profile and the complexity of the project. However, several common steps are involved.

Proper preparation is paramount. This includes ensuring a straight and level surface, properly flashed openings, and appropriate weather protection.

- Starting the First Course: Begin at a corner or a pre-determined starting point, ensuring proper alignment and spacing.

- Applying Fasteners: Use galvanized nails or screws designed specifically for fiber cement siding, ensuring proper penetration and spacing to avoid cracking.

- Overlapping Laps: Maintain consistent overlap between siding panels according to the manufacturer’s specifications. This is crucial for water management.

- Caulking and Sealing: Seal all joints and gaps with high-quality caulk to prevent water intrusion. Pay close attention to corners and around windows and doors.

- Finishing Touches: Install trim, flashing, and other accessories as needed to complete the installation.

Aesthetic Appeal of Fiber Cement Lap Siding Styles

The aesthetic appeal of fiber cement lap siding varies greatly depending on the chosen profile, color, and texture. For instance, smooth, light-colored siding lends itself to contemporary or minimalist designs, while wood-grain textured siding can enhance the charm of traditional or rustic homes. Darker colors can create a dramatic and modern look, especially when used with a shadow line profile. The use of beaded lap siding can enhance the visual interest of smaller homes.

Maintenance Requirements for Fiber Cement Lap Siding

Fiber cement siding is relatively low-maintenance. However, regular cleaning and occasional inspections are recommended to prevent damage and maintain its aesthetic appeal.

Cleaning typically involves washing the siding with a mild detergent and water, using a soft-bristled brush to remove dirt and debris. Regular inspections should focus on identifying any cracks, damage, or signs of water intrusion. Prompt repairs are essential to prevent more extensive damage.

Installation and Maintenance of Fiber Cement Lap Siding

Fiber cement lap siding offers a durable and attractive exterior cladding solution, but its longevity and aesthetic appeal depend heavily on proper installation and consistent maintenance. This section details the crucial steps involved in installation, emphasizing safety, and provides comprehensive guidance on cleaning, care, and addressing common issues.

Fiber Cement Lap Siding Installation: A Step-by-Step Guide

Proper installation is paramount to ensuring the longevity and performance of your fiber cement siding. Failure to follow these steps can lead to premature damage and costly repairs. Always consult the manufacturer’s specific instructions as they may vary slightly depending on the product.

- Preparation: Begin by thoroughly inspecting the existing wall surface. Repair any damaged areas, ensuring a smooth, level substrate. This may involve removing old siding, patching holes, and addressing any moisture issues. Proper preparation is key to a successful installation.

- Framing and Sheathing: Install appropriate framing and sheathing to provide a solid base for the siding. Ensure proper ventilation to prevent moisture buildup. Use pressure-treated lumber for optimal durability and resistance to rot.

- Water-Resistant Barrier: Apply a water-resistant barrier, such as house wrap, to protect the underlying structure from moisture. Overlapping seams are crucial to prevent water penetration. This step significantly contributes to the longevity of the siding.

- Flashing Installation: Install flashing around windows, doors, and other openings to prevent water from entering the wall system. Proper flashing is critical for preventing water damage and leaks.

- Siding Installation: Begin installing the siding at the bottom of the wall, working your way up. Maintain consistent overlap between each lap, ensuring proper alignment and spacing. Use appropriate fasteners, ensuring they are properly driven to avoid damaging the siding.

- Caulking and Sealing: Caulk all seams and joints to prevent water infiltration. Pay particular attention to areas around windows, doors, and corners. Use high-quality, exterior-grade caulk.

- Finishing Touches: Install trim and accessories as needed to complete the installation. Ensure all components are securely fastened and properly aligned.

Safety Precautions During Installation

Fiber cement siding installation requires working at heights and handling potentially sharp materials. Prioritize safety throughout the process:

- Always use appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator to prevent inhalation of dust.

- Use proper scaffolding or ladders to safely reach working heights. Ensure stability and secure footing at all times.

- Follow all manufacturer’s safety guidelines and warnings. Consult a professional if you are unsure about any aspect of the installation.

Cleaning and Care of Fiber Cement Lap Siding

Regular cleaning helps maintain the appearance and longevity of fiber cement siding.

Cleaning should be done at least once or twice a year, depending on environmental factors. Use a soft-bristled brush and a mild detergent solution. Avoid harsh chemicals or abrasive cleaners, as these can damage the siding’s surface. For stubborn stains, consider using a pressure washer, but maintain a safe distance to prevent damage. Always rinse thoroughly with clean water after cleaning.

Addressing Common Issues in Fiber Cement Lap Siding

Despite its durability, fiber cement siding can experience issues over time.

Cracks: Minor cracks can often be repaired with a suitable patching compound. For larger cracks, professional repair may be necessary. Early detection and repair are crucial to prevent further damage. Discoloration: Regular cleaning can often address minor discoloration. For more persistent discoloration, consider repainting or restaining the siding. Water Damage: Water damage usually indicates a problem with flashing or caulking. Address these issues promptly to prevent further damage to the underlying structure. Prompt identification and repair of water ingress points are essential to avoid structural problems.

Potential Installation Problems and Solutions

Several issues can arise during installation.

Improper Fastening: Using incorrect fasteners or driving them too deeply can damage the siding. Use the recommended fasteners and ensure they are driven to the correct depth. Uneven Surfaces: Uneven surfaces can lead to gaps and alignment issues. Address uneven surfaces before installing the siding. Moisture Issues: Failure to properly manage moisture can lead to rot and damage. Ensure proper ventilation and water management throughout the installation process. Addressing these potential problems proactively can prevent significant issues later on.

Cost and Durability of Fiber Cement Lap Siding

Fiber cement siding offers a compelling blend of aesthetics, durability, and longevity, but understanding its cost-effectiveness requires a comprehensive comparison with other siding materials and a thorough examination of factors influencing its lifespan. This section will analyze the initial investment, ongoing maintenance, and long-term value proposition of fiber cement siding, providing a clear picture of its total cost of ownership and environmental impact.

Cost Comparison of Fiber Cement Siding with Other Materials

The initial cost of siding varies considerably depending on material, style, and labor. Fiber cement generally falls within the mid-range price bracket. However, its extended lifespan and lower maintenance requirements often translate to significant long-term savings. The following table compares fiber cement to popular alternatives:

| Material | Initial Cost (per sq ft, approximate) | Maintenance Cost (per sq ft, per year, approximate) | Lifespan (years) |

|---|---|---|---|

| Fiber Cement | $8-$15 | $0.10-$0.50 | 50-80 |

| Vinyl | $4-$8 | $0.05-$0.20 | 20-30 |

| Wood | $6-$12 | $0.50-$2.00 | 15-30 |

| Aluminum | $7-$12 | $0.20-$0.70 | 30-50 |

*Note: These are approximate costs and can vary widely based on location, labor rates, and specific product choices. Consult local contractors for accurate pricing in your area.*

Factors Affecting the Longevity and Durability of Fiber Cement Siding

Several factors significantly impact the lifespan and performance of fiber cement siding. Proper installation is paramount, ensuring the siding is correctly fastened and sealed to prevent water damage. Regular cleaning helps remove dirt and debris, preventing staining and deterioration. Climate plays a crucial role; harsh weather conditions, such as extreme temperature fluctuations and frequent freeze-thaw cycles, can accelerate weathering and potential cracking. Finally, the quality of the fiber cement product itself – specifically its cement-to-fiber ratio and the presence of additives that enhance durability – influences its long-term performance.

Calculating the Total Cost of Ownership

Calculating the total cost of ownership (TCO) provides a comprehensive understanding of the overall expense of fiber cement siding over its lifespan. This calculation considers the initial cost, maintenance expenses, and potential replacement costs.

Total Cost of Ownership = Initial Cost + (Annual Maintenance Cost x Lifespan) + Replacement Cost

For example, consider a 1,000 sq ft house with fiber cement siding costing $10/sq ft. With annual maintenance estimated at $0.25/sq ft and a lifespan of 50 years, the TCO would be:

$10,000 (Initial Cost) + ($0.25/sq ft x 1,000 sq ft x 50 years) + $0 = $22,500

This assumes no major repairs or replacements are needed within the 50-year period. In contrast, vinyl siding with a 20-year lifespan might require replacement, significantly impacting its TCO.

Environmental Impact of Fiber Cement Siding

Fiber cement siding offers a relatively environmentally friendly option compared to some alternatives. It’s composed of sustainable materials such as cement, sand, and cellulose fibers, reducing reliance on resource-intensive materials like vinyl. However, the manufacturing process does have an environmental footprint due to energy consumption and the emission of greenhouse gases. Compared to wood siding, fiber cement requires less ongoing maintenance, reducing the environmental impact associated with the production and transportation of replacement materials. The choice between fiber cement and other materials requires a balanced assessment of both initial manufacturing impacts and long-term maintenance considerations.

Visual Representation of Fiber Cement Lap Siding

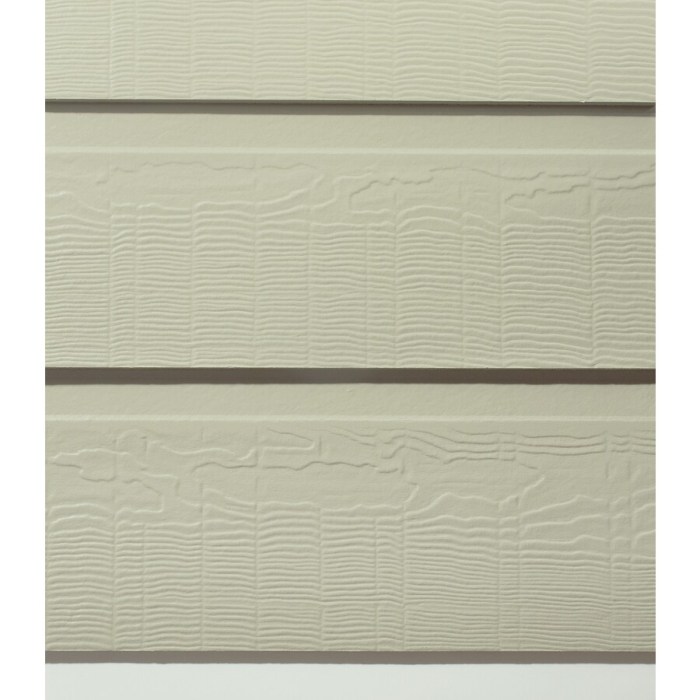

Fiber cement lap siding offers a diverse range of visual options, impacting a home’s aesthetic significantly. Its appearance is determined by a combination of factors including profile, color, texture, and the interplay of light and shadow. Understanding these elements is crucial for homeowners seeking to enhance their curb appeal.

Fiber cement siding’s visual appeal stems from its ability to mimic the look of natural materials like wood, while offering superior durability and low maintenance. The texture can range from smooth to deeply textured, replicating the grain of wood or the rough surface of stone. Color choices are extensive, allowing for a wide array of design possibilities to complement various architectural styles.

Texture and Color Variations

The texture of fiber cement lap siding contributes significantly to its overall visual impact. Some manufacturers offer smooth finishes for a clean, modern look, while others provide deeply textured options that emulate the natural variations found in wood grain. This textural variety adds depth and visual interest to the siding. Color options are equally diverse, ranging from traditional earth tones and muted grays to bold, vibrant hues. The color palette allows for seamless integration with existing landscaping and architectural features. For instance, a warm, earthy brown siding can complement a rustic farmhouse, while a crisp white siding can accentuate a contemporary design. Custom color-matching options are also available from many manufacturers, allowing for unparalleled design flexibility.

Profiles and Finishes

Fiber cement lap siding comes in a variety of profiles, each contributing a unique aesthetic to the overall design. The most common profiles include standard lap siding, which offers a classic look, and beaded lap siding, which features a subtle raised bead along the edge of each panel, adding a touch of traditional charm. Other profiles, such as shiplap or Dutch lap, offer more pronounced variations in the panel design. Finishes also contribute to the visual effect. Some finishes aim for a smooth, painted look, while others have a textured finish designed to mimic the appearance of natural wood. The choice of profile and finish significantly impacts the visual appeal of the siding and the overall style of the home. A home with a modern design might benefit from smooth, contemporary-colored siding, while a traditional home might be better suited to a textured finish and a more classic color palette.

Effect of Light and Shadow

The way light interacts with fiber cement lap siding dramatically influences its appearance. The interplay of light and shadow creates depth and texture, highlighting the details of the siding’s profile and finish. On a sunny day, the light can accentuate the subtle variations in color and texture, creating a dynamic and visually appealing façade. Conversely, on an overcast day, the siding will appear more muted, but still maintain its overall aesthetic appeal. The orientation of the house and the angle of the sun will further influence the appearance of the siding throughout the day and across the seasons. A home facing south will receive more direct sunlight, leading to more pronounced shadows and highlights on the siding compared to a home facing north. The effect of light and shadow can also be manipulated through careful consideration of the siding’s color and texture. Darker colors will absorb more light, creating a more dramatic effect, while lighter colors will reflect more light, giving the siding a brighter, more airy feel.

Enhancing Curb Appeal

Fiber cement lap siding offers exceptional versatility in enhancing a home’s curb appeal. The wide array of colors, textures, and profiles allows homeowners to tailor the siding to complement the architectural style and landscaping of their property. For example, a Craftsman-style home might benefit from a darker, earth-toned siding with a textured finish, while a contemporary home might look stunning with sleek, smooth siding in a bold color. Consider a light grey siding with dark trim for a classic, clean look on a colonial home, or a warm beige with contrasting white trim for a traditional, inviting feel on a ranch-style home. By thoughtfully choosing the right color scheme and siding profile, homeowners can significantly improve their home’s visual appeal and increase its market value. The durability and low-maintenance nature of fiber cement siding further contribute to its long-term appeal, ensuring the home maintains its enhanced curb appeal for years to come.

Ultimately, the decision to choose fiber cement lap siding hinges on a careful consideration of your budget, aesthetic preferences, and long-term goals for your home. Its durability, low maintenance requirements, and attractive appearance make it a strong contender for homeowners prioritizing a lasting, visually appealing exterior. By understanding the nuances of installation, maintenance, and cost considerations Artikeld in this guide, you can confidently navigate the process and make an informed choice that enhances both the beauty and value of your property. Remember to factor in regional climate conditions and consult with professionals for complex installations to ensure optimal results.

FAQ Summary

What is the lifespan of fiber cement lap siding?

With proper installation and maintenance, fiber cement siding can last 50 years or more.

Is fiber cement siding susceptible to insect damage?

No, unlike wood, fiber cement is resistant to insect infestation and rot.

Can I paint fiber cement siding?

Yes, fiber cement siding can be painted, but it’s crucial to use a paint specifically designed for exterior use on this material.

How much does professional installation cost?

The cost varies greatly depending on factors such as location, house size, and siding complexity. Get multiple quotes from reputable contractors.

Does fiber cement siding require special cleaning products?

Generally, a simple pressure washing is sufficient. Avoid abrasive cleaners that could damage the surface.