Fiber cement trim offers a durable and aesthetically pleasing alternative to traditional exterior trim materials. This comprehensive guide delves into the composition, manufacturing process, and diverse applications of fiber cement trim, comparing it to wood, vinyl, and aluminum. We’ll explore its installation, maintenance, cost-effectiveness, environmental impact, and the myriad ways it can enhance a home’s curb appeal and architectural style. Discover how fiber cement trim can elevate your next project, from subtle enhancements to bold design statements.

From understanding its unique properties to mastering installation techniques, this guide provides a complete overview, equipping you with the knowledge to make informed decisions about incorporating fiber cement trim into your building or renovation plans. We’ll cover everything from choosing the right color and finish to understanding the long-term cost implications and environmental considerations. Prepare to be inspired by the versatility and enduring quality of fiber cement trim.

What is Fiber Cement Trim?

Fiber cement trim is a durable and versatile exterior building material used to enhance the aesthetic appeal and protect the structural elements of a home or building. It offers a long-lasting, low-maintenance alternative to traditional wood trim. This composite material combines the strength of cement with the flexibility of cellulose fibers, creating a product that resists rot, insects, and fire.

Fiber Cement Trim Composition and Manufacturing

Fiber cement trim is composed primarily of Portland cement, cellulose fibers (often from recycled wood pulp), and silica sand. These ingredients are mixed with water to form a slurry, which is then shaped using various molding techniques. The shaped pieces are then cured under high pressure and temperature, a process that hardens the material and enhances its strength and durability. Finally, the cured trim pieces undergo finishing processes, which may include painting or texturing, to achieve the desired aesthetic.

Fiber Cement Trim Compared to Other Exterior Trim Materials

The following table compares fiber cement trim to other popular exterior trim materials, highlighting key differences in durability, cost, maintenance, and aesthetics. This comparison helps homeowners and builders make informed decisions based on their specific needs and preferences. Cost estimates are averages and can vary based on location, supplier, and specific product features.

| Material | Durability | Cost | Maintenance | Aesthetics |

|---|---|---|---|---|

| Fiber Cement | High; resists rot, insects, and fire. Typically lasts 50 years or more. | Medium to High; generally more expensive than vinyl but less than high-end wood. | Low; occasional cleaning and repainting may be needed after many years. | Versatile; can be painted and textured to mimic wood or other materials. |

| Wood | Medium to High (depending on wood type); susceptible to rot, insects, and weather damage. | Medium to High (depending on wood type); can be very expensive for high-quality, durable woods. | High; requires regular painting, staining, and maintenance to prevent damage. | Classic and natural look; many wood types and finishes available. |

| Vinyl | Medium; resists rot and insects but can be damaged by impact. | Low to Medium; generally the most affordable option. | Low; typically requires minimal cleaning. | Limited aesthetic options; often has a plastic appearance. |

| Aluminum | High; resists rot, insects, and fire; very durable. | Medium to High; cost varies depending on finish and style. | Low; requires minimal maintenance; may need occasional cleaning. | Modern and sleek look; available in various colors and finishes. |

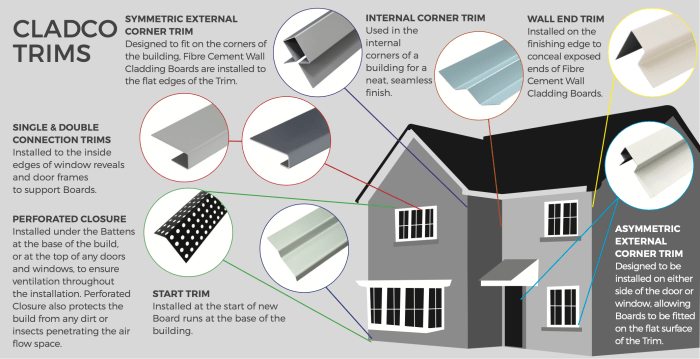

Applications of Fiber Cement Trim

Fiber cement trim boasts exceptional versatility, finding its place in a wide array of architectural styles and exterior design applications. Its durability, low maintenance, and aesthetic appeal make it a popular choice for homeowners and builders alike, enhancing both the visual and structural integrity of a building. This section will explore various applications, showcasing its transformative power in enhancing curb appeal and creating stunning exterior designs.

Fiber cement trim’s adaptability allows for seamless integration into diverse architectural styles, significantly impacting a home’s overall aesthetic. Its ability to mimic the look of wood, stone, or stucco without the associated maintenance issues makes it a highly sought-after material.

Architectural Styles Utilizing Fiber Cement Trim

The enduring nature and design flexibility of fiber cement trim make it a suitable choice for a broad range of architectural styles. Its adaptability to different design aesthetics contributes to its widespread use.

- Craftsman: Fiber cement trim’s ability to create intricate details and strong horizontal lines complements the Craftsman style’s emphasis on handcrafted elements and natural materials. The trim can be used to accentuate the porch, windows, and gables, creating a visually rich and inviting façade.

- Victorian: The ornate detailing and layered architectural elements of Victorian homes are beautifully enhanced by fiber cement trim. Its ability to replicate the look of wood without the upkeep makes it an ideal choice for reproducing intricate molding and trim work.

- Farmhouse: The clean lines and simple elegance of the farmhouse style are beautifully complemented by fiber cement trim. Its versatility allows for both subtle and bold applications, enhancing the home’s rustic charm without overwhelming the overall design.

- Modern: Even in contemporary designs, fiber cement trim offers a sleek and sophisticated look. Its clean lines and ability to be painted in various colors allow for seamless integration into minimalist and modern architectural aesthetics.

Enhancing Curb Appeal with Fiber Cement Trim

Fiber cement trim significantly elevates a home’s curb appeal through its ability to add visual interest, create a cohesive design, and improve the overall appearance of the exterior. The material’s durability ensures long-lasting beauty and minimal maintenance, further contributing to its attractiveness.

Strategic placement of fiber cement trim can highlight architectural features, creating focal points that draw the eye and add depth to the façade. Whether used to frame windows, accentuate gables, or create decorative cornices, fiber cement trim adds a touch of elegance and sophistication. Furthermore, its resistance to weathering, insects, and rot ensures that the enhanced curb appeal endures for years to come, saving homeowners time and money on maintenance and repairs.

Exterior House Designs Showcasing Fiber Cement Trim

The following examples illustrate the diverse applications of fiber cement trim in creating visually striking and structurally sound exterior designs. Each design showcases a unique approach to integrating the material into different architectural elements.

Design 1: Modern Farmhouse with Bold Accents: This design features a classic farmhouse silhouette with a modern twist. Wide, crisp white fiber cement trim is used to frame large windows and create a prominent cornice. Dark gray fiber cement siding is used for the main body of the house, providing a striking contrast to the bright trim. The overall effect is clean, sophisticated, and inviting.

Design 2: Craftsman Bungalow with Intricate Detailing: This design incorporates intricate fiber cement trim to replicate the look of traditional wood detailing found in Craftsman bungalows. The trim is used extensively around windows, doors, and along the roofline, creating a rich and layered appearance. A warm, earthy tone is chosen for the trim, complementing the natural wood elements and stone accents of the house.

Design 3: Victorian Revival with Ornate Molding: This design showcases the versatility of fiber cement trim in recreating the elaborate molding and trim work characteristic of Victorian architecture. The trim is used to create ornate window surrounds, decorative cornices, and intricate fascia details. A lighter color palette is employed, allowing the intricate detailing to stand out against the darker siding. The overall effect is elegant, timeless, and visually captivating.

Installation and Maintenance of Fiber Cement Trim

Fiber cement trim offers a durable and attractive alternative to traditional wood trim, but proper installation and maintenance are crucial for maximizing its lifespan and aesthetic appeal. Understanding the process, from initial cutting to ongoing care, ensures a long-lasting, beautiful finish to your home’s exterior.

Step-by-Step Installation Guide

Careful planning and precise execution are key to a successful fiber cement trim installation. The following steps Artikel a typical installation process. Remember to always consult the manufacturer’s specific instructions for your chosen product.

- Preparation: Begin by ensuring you have all necessary tools and materials, including a measuring tape, saw (circular saw with a carbide-tipped blade is recommended), safety glasses, dust mask, gloves, caulk, nails or screws appropriate for fiber cement, and a level. Accurately measure and mark the areas where the trim will be installed. Prepare the surfaces by cleaning them thoroughly to ensure proper adhesion.

- Cutting the Trim: Use a sharp carbide-tipped blade to cut the fiber cement trim to the required lengths. Wear a dust mask to prevent inhalation of fine particles. Make precise cuts to minimize waste and ensure a clean fit. Consider using a miter saw for accurate angled cuts.

- Installation: Position the trim pieces according to your markings, ensuring they are level and aligned. Secure the trim using nails or screws, spacing fasteners according to manufacturer recommendations. Pre-drilling pilot holes is often recommended to prevent cracking.

- Caulking: Apply a high-quality exterior-grade caulk to all joints and gaps between the trim and the surrounding surfaces. This will prevent water penetration and enhance the overall appearance. Smooth the caulk for a neat finish.

- Finishing: Once the caulk has dried, inspect the installation for any gaps or imperfections. Make any necessary adjustments or repairs. Consider applying a sealant or paint to further protect the fiber cement trim and enhance its aesthetic appeal.

Cutting and Finishing Techniques, Fiber cement trim

Proper cutting and finishing techniques are vital for achieving a professional-looking installation and preventing damage to the trim.

Cutting fiber cement trim requires specialized tools and safety precautions. A circular saw with a carbide-tipped blade is recommended for straight cuts, while a miter saw is ideal for angled cuts. Always wear safety glasses and a dust mask to protect against flying debris and silica dust. For intricate cuts, a jigsaw with a fine-tooth blade can be used, but proceed with caution. Scoring the material lightly before cutting can help prevent chipping.

Finishing involves carefully caulking all joints and gaps, ensuring a watertight seal. Properly applied caulk prevents moisture intrusion, which can lead to damage and deterioration of the trim. After caulking, allow sufficient drying time before applying any paint or sealant. Sanding may be necessary to smooth out rough edges or imperfections before painting.

Routine Maintenance Procedures

Regular maintenance is essential for prolonging the life and beauty of fiber cement trim.

- Annual Inspection: Conduct a thorough visual inspection at least once a year, checking for any signs of damage, such as cracks, loose fasteners, or water damage.

- Cleaning: Clean the trim regularly using a mild detergent and water. Avoid using abrasive cleaners or harsh chemicals that could damage the surface. A soft-bristled brush or sponge can be used to remove dirt and debris.

- Caulk Repair: Inspect and repair any damaged or cracked caulking. Reapply caulk as needed to maintain a watertight seal.

- Repainting/Resealing: Depending on the climate and exposure to the elements, repainting or resealing may be necessary every few years to protect the trim from the effects of UV radiation and moisture.

- Fastener Check: Periodically check all fasteners to ensure they are secure. Tighten or replace any loose fasteners as needed.

Advantages and Disadvantages of Fiber Cement Trim

Fiber cement trim offers a compelling alternative to traditional wood and vinyl options, boasting a unique blend of benefits and drawbacks. Understanding these aspects is crucial for making an informed decision about its suitability for your project. This section will delve into the key advantages and disadvantages, providing a balanced perspective to aid in your selection process.

Advantages of Fiber Cement Trim

Fiber cement trim presents several significant advantages that make it a popular choice for many construction projects. Its robust composition translates to exceptional durability and longevity, significantly reducing the need for frequent replacements.

| Advantage | Description |

|---|---|

| Durability and Longevity | Fiber cement trim is highly resistant to rot, decay, insect infestation, and moisture damage, resulting in a significantly longer lifespan compared to wood trim. This translates to lower long-term costs associated with replacements and repairs. A properly installed fiber cement trim can last for decades with minimal maintenance. |

| Low Maintenance | Its inherent resistance to the elements minimizes the need for regular painting, staining, or sealing. While occasional cleaning may be necessary, the overall maintenance requirements are substantially lower than those of wood trim. This reduces both time and cost commitments over the trim’s lifespan. |

| Pest Resistance | Unlike wood, fiber cement is impervious to termites and other wood-boring insects. This significantly reduces the risk of damage and the associated costs of pest control and repairs. This feature is particularly advantageous in regions with high pest populations. |

| Fire Resistance | Fiber cement is a non-combustible material, offering a significant safety advantage over wood trim in the event of a fire. This inherent fire resistance contributes to enhanced building safety and can potentially reduce insurance premiums. |

| Versatile Appearance | Fiber cement trim is available in a variety of profiles, colors, and textures, allowing for seamless integration with diverse architectural styles. This versatility provides significant design flexibility to complement various aesthetic preferences. |

Disadvantages of Fiber Cement Trim

While offering substantial benefits, fiber cement trim also presents some drawbacks that need careful consideration. These factors can influence the overall cost-effectiveness and practicality of using this material.

| Disadvantage | Description |

|---|---|

| Cost | Fiber cement trim is generally more expensive than wood or vinyl alternatives. The initial investment is higher, but the long-term cost savings from reduced maintenance and extended lifespan can offset this initial expense over time. |

| Weight | Fiber cement is heavier than wood or vinyl, requiring more robust installation methods and potentially impacting labor costs. This increased weight may also necessitate additional structural support in certain applications. |

| Potential for Cracking | Improper installation or exposure to extreme temperature fluctuations can lead to cracking. Careful installation practices and appropriate expansion joint considerations are crucial to mitigate this risk. |

| Difficult to Cut and Shape | Compared to wood, fiber cement requires specialized tools and techniques for cutting and shaping. This can increase installation time and potentially labor costs if not handled by experienced professionals. |

| Susceptibility to Impact Damage | While durable, fiber cement can be susceptible to damage from significant impacts. This is particularly relevant during the installation process and in areas prone to accidental collisions. |

Environmental Impact of Fiber Cement Trim

Fiber cement trim, while offering numerous advantages in terms of durability and aesthetics, presents a complex environmental profile stemming from its manufacturing process and eventual disposal. Understanding this impact is crucial for responsible material selection and lifecycle management within the construction industry. This section will delve into the environmental considerations associated with fiber cement trim, comparing it to alternatives and exploring sustainable practices to minimize its footprint.

Manufacturing fiber cement trim involves several stages with associated environmental consequences. The production of cement, a key component, is energy-intensive and releases significant greenhouse gases, primarily carbon dioxide (CO2), into the atmosphere. The extraction and processing of other raw materials, such as cellulose fibers and sand, also contribute to environmental impacts, including habitat disruption and water consumption. Furthermore, the manufacturing process itself can generate air and water pollution if not managed properly.

Manufacturing Process Emissions

The cement industry is a major source of global CO2 emissions. The high temperatures required for cement production contribute significantly to this, along with the chemical reactions involved. While advancements in cement manufacturing techniques are aiming to reduce emissions, the carbon footprint remains substantial. The extraction of raw materials like sand can also lead to soil erosion and habitat destruction, especially if unsustainable mining practices are employed. The use of cellulose fibers, while often sourced from sustainable forestry, still involves transportation and processing, contributing to the overall environmental impact. The energy consumed during the manufacturing process, from powering machinery to transporting materials, further increases the carbon footprint. For example, a large-scale fiber cement trim manufacturer might use hundreds of megawatt-hours of electricity annually, a significant portion of which could come from non-renewable sources.

Comparison with Alternative Materials

Compared to alternatives like vinyl siding or wood, fiber cement trim offers a more favorable environmental profile in certain aspects. Vinyl siding, while requiring less energy to manufacture, is derived from petroleum, a non-renewable resource, and often contains harmful chemicals. Its disposal poses challenges due to its non-biodegradability. Wood, while a renewable resource, faces issues with deforestation and the potential for the use of unsustainable logging practices. Furthermore, wood trim is susceptible to rot, insect infestation, and requires more frequent maintenance and replacement, leading to an overall higher environmental impact over its lifetime. However, sustainably sourced and responsibly managed wood can significantly reduce its environmental impact. The environmental performance of fiber cement trim relative to these alternatives depends heavily on factors such as the manufacturing processes employed, the sourcing of raw materials, and end-of-life management.

Sustainable Practices in Fiber Cement Trim Lifecycle

Incorporating sustainable practices throughout the lifecycle of fiber cement trim can significantly mitigate its environmental impact. This includes sourcing raw materials responsibly, employing energy-efficient manufacturing processes, and promoting recycling or responsible disposal at the end of the product’s life. For instance, utilizing recycled materials in the manufacturing process can reduce reliance on virgin resources and decrease the overall environmental footprint. Investing in renewable energy sources to power manufacturing facilities can significantly reduce greenhouse gas emissions. Additionally, promoting the use of low-embodied-carbon cement formulations can further decrease the CO2 emissions associated with cement production. Finally, implementing efficient transportation strategies can minimize fuel consumption and associated emissions. Furthermore, manufacturers should actively explore end-of-life solutions, such as recycling programs, to reduce landfill waste. The development of more readily recyclable fiber cement formulations is also a crucial area for future innovation.

Cost Considerations for Fiber Cement Trim

Fiber cement trim offers a durable and aesthetically pleasing alternative to traditional materials, but its cost is a significant factor to consider before committing to a project. Understanding the various cost components, from initial purchase to long-term maintenance, is crucial for making an informed decision. This section will break down the costs involved and compare them to other common trim materials, helping you determine the long-term value proposition of fiber cement.

Material Costs

The price of fiber cement trim varies depending on several factors, including the manufacturer, the thickness and profile of the trim pieces, and the region. Generally, expect to pay more for wider, more ornate profiles. For instance, a simple 1×6 board might cost between $2 and $5 per linear foot, while more elaborate crown molding could range from $8 to $20 per linear foot. Bulk purchasing can often result in discounts, but accurate costing requires obtaining quotes from local suppliers based on your specific project requirements. Comparing prices from multiple suppliers is strongly recommended to ensure you’re getting the best possible deal.

Installation Costs

Labor costs for installing fiber cement trim are significant. Professional installation is generally recommended, especially for intricate designs, to ensure proper alignment, cutting, and fastening. The hourly rate for experienced installers varies geographically, but expect to pay anywhere from $50 to $100 per hour. The total labor cost will depend on the complexity of the project, the amount of trim needed, and the installer’s experience. Simple projects might cost a few hundred dollars, while extensive renovations could reach thousands. DIY installation is possible, but requires specialized tools and a considerable amount of time and skill; miscalculations could lead to wasted materials and increased costs.

Maintenance Costs

Fiber cement trim is known for its low maintenance requirements. Unlike wood, it doesn’t require regular painting or staining. However, minor repairs might be needed over time. These repairs typically involve replacing damaged sections. The cost will depend on the extent of the damage and the cost of replacement materials and labor. In most cases, the long-term maintenance costs for fiber cement trim are significantly lower than for wood, which may require repainting every few years.

Long-Term Cost Comparison

When comparing the long-term cost-effectiveness of fiber cement trim to other materials like wood or vinyl, several factors come into play. While the initial cost of fiber cement might be higher, its durability and low maintenance significantly reduce long-term expenses. Wood trim, for example, requires regular painting or staining, increasing costs over time. Vinyl trim might be initially cheaper but may not be as durable, potentially requiring replacement sooner than fiber cement. A thorough cost analysis should consider the lifespan of each material, the frequency and cost of maintenance, and the potential for premature failure.

Scenario: Total Cost for a House Renovation

Let’s consider a hypothetical scenario: a homeowner is renovating the exterior trim of a 2,000 square foot house. Assume the project requires approximately 500 linear feet of fiber cement trim (various profiles) at an average cost of $10 per linear foot, totaling $5,000 in materials. Professional installation is estimated at $2,000 (40 hours at $50/hour). This brings the total cost to $7,000. In contrast, a similar project using wood might cost $4,000 initially, but would likely require repainting every 5 years at a cost of $1,000 per repaint, exceeding the cost of fiber cement over the long term. Vinyl, while potentially cheaper initially, might need replacement within 10-15 years, incurring significant replacement costs. Therefore, despite a higher upfront cost, fiber cement can prove to be a more cost-effective solution in the long run.

Aesthetic Considerations

Fiber cement trim offers a remarkable versatility in aesthetics, allowing homeowners and architects to achieve a wide range of visual effects and complement diverse architectural styles. Its ability to mimic the appearance of other materials, coupled with its inherent durability, makes it a compelling choice for enhancing curb appeal and adding architectural character. The careful selection of color and finish is crucial in maximizing its aesthetic impact.

The color and finish of fiber cement trim significantly influence the overall appearance of a building. A wide palette of colors is available, ranging from classic whites and creams to bold earth tones and deep, saturated hues. These colors can be applied using various finishes, including smooth, textured, or wood-grain effects, further expanding the design possibilities. The choice of color and finish should consider the surrounding environment, the building’s architectural style, and the desired visual impact.

Color Options and Their Visual Impact

The color of fiber cement trim plays a vital role in setting the overall tone and style of a home. Lighter colors, such as white or cream, create a clean, crisp, and airy feel, often associated with traditional or modern styles. They reflect light, making the building appear brighter and larger. Darker colors, on the other hand, create a more dramatic and sophisticated look, often used to accentuate architectural details or create a sense of contrast. Earth tones, such as browns, grays, and greens, blend seamlessly with natural surroundings, creating a harmonious and understated aesthetic. Bold colors, like deep blues or reds, can be used to make a striking statement, adding a vibrant and contemporary touch. For instance, a deep navy blue trim against a white stucco house creates a sophisticated nautical feel, while a warm terracotta trim complements a Mediterranean-style home.

Fiber Cement Trim’s Role in Creating Visual Interest and Architectural Detail

Fiber cement trim is not merely a functional element; it serves as a powerful tool for enhancing the visual appeal of a building. Its ability to create sharp lines, intricate details, and contrasting textures adds depth and visual interest to the façade. By strategically placing trim around windows, doors, eaves, and other architectural features, designers can emphasize these elements and create a sense of balance and proportion. The use of different widths and profiles of trim can also add visual complexity and create a more dynamic and engaging design. For example, wide, bold trim can draw attention to key architectural features, while thinner trim can be used to create subtle accents and delineate different areas of the façade. This careful manipulation of visual weight and scale significantly impacts the overall aesthetic impression.

Creating Different Visual Effects with Fiber Cement Trim

Fiber cement trim’s versatility extends to its ability to create a range of visual effects. The use of shadow lines, achieved by employing contrasting colors or creating depth through layering, can add drama and sophistication. Textured finishes, such as wood grain or stucco, introduce visual interest and can complement the texture of other building materials. The interplay of light and shadow on the trim further enhances its aesthetic impact. For example, using a darker color trim on a sun-facing wall will create more prominent shadows, adding depth and visual interest. Conversely, lighter trim on a shaded area will soften the shadows and create a sense of lightness and airiness. The strategic use of varying widths and profiles of trim can also create a layered effect, enhancing the visual depth and complexity of the building’s façade.

Ultimately, the decision to use fiber cement trim hinges on a careful consideration of its advantages and disadvantages within the context of your specific project. While the initial cost may be higher than some alternatives, the long-term durability, low maintenance requirements, and enhanced aesthetic appeal often outweigh the upfront investment. By understanding its properties, applications, and installation process, you can confidently harness the power of fiber cement trim to create a stunning and enduring exterior for your home or building. The superior longevity and aesthetic versatility of fiber cement trim make it a compelling choice for discerning homeowners and builders alike.

Quick FAQs: Fiber Cement Trim

Can fiber cement trim be painted?

Yes, fiber cement trim can be painted, but it requires a primer specifically designed for this material to ensure proper adhesion and longevity.

How long does fiber cement trim last?

With proper installation and maintenance, fiber cement trim can last for several decades, significantly outlasting many other trim materials.

Is fiber cement trim susceptible to rot or insect damage?

No, unlike wood, fiber cement trim is inherently resistant to rot, insect infestation, and fungal growth.

What tools are needed for cutting fiber cement trim?

Specialized tools like a wet saw with a diamond blade are recommended for precise and safe cutting to avoid inhaling dust.

How do I clean fiber cement trim?

Regular cleaning with soap and water is usually sufficient. For stubborn stains, a pressure washer can be used, but avoid excessive pressure.