Lp smart panel – LP SmartPanel revolutionizes exterior cladding, offering a durable and sustainable alternative to traditional wood. This engineered wood product boasts superior strength, dimensional stability, and resistance to moisture and insects, making it ideal for a variety of residential and commercial applications. From its innovative manufacturing process to its long-term environmental benefits, we delve into every aspect of LP SmartPanel, providing a complete guide for homeowners, builders, and architects.

This in-depth exploration covers everything from the core features and functionalities of LP SmartPanel to its installation, maintenance, and the comprehensive warranty offered by LP Building Products. We’ll examine its performance in diverse climates, compare it to competing materials, and showcase real-world examples of its successful implementation in various construction projects. Prepare to gain a thorough understanding of this versatile and increasingly popular building material.

LP SmartPanel Product Overview

LP SmartPanel engineered wood siding offers a durable and attractive alternative to traditional wood siding. Its innovative manufacturing process and advanced materials provide superior performance in terms of rot resistance, insect damage prevention, and overall longevity. This overview details the key features, manufacturing process, and competitive advantages of LP SmartPanel.

Core Features and Functionalities of LP SmartPanel

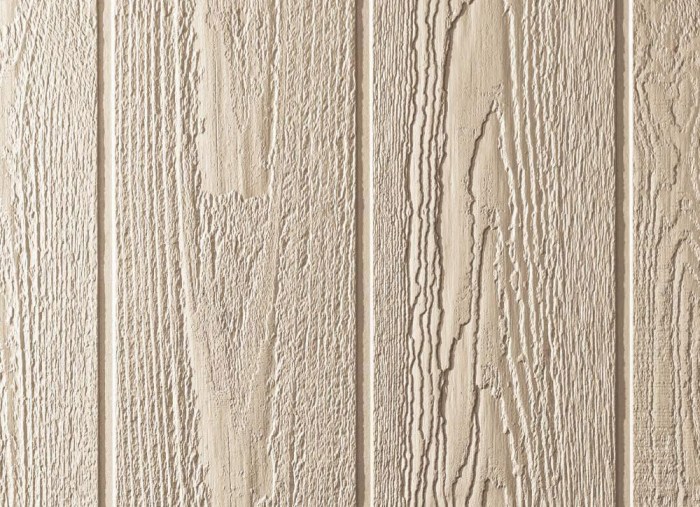

LP SmartPanel is engineered wood siding composed of strands of wood fiber, resin, and wax, combined under high pressure and heat. This process creates a dense, strong panel resistant to moisture and insect damage. Key features include its dimensional stability, which minimizes warping and shrinking; its resistance to rot and fungal decay; and its paintability, allowing for customization and aesthetic versatility. The panels are available in various textures and profiles to match diverse architectural styles. They also offer superior impact resistance compared to traditional wood.

Manufacturing Process of LP SmartPanel

The manufacturing of LP SmartPanel involves several key steps. First, wood fibers are harvested and processed into strands. These strands are then combined with proprietary resins and waxes, creating a composite material. This mixture is then formed into panels under immense pressure and heat. This process bonds the wood strands and the resin together, creating a dense and stable product. Finally, the panels are treated with a protective coating to enhance their weather resistance and durability. The entire process ensures a consistent product with high quality and performance characteristics.

Comparison of LP SmartPanel to Traditional Wood Siding and Other Competing Products

Compared to traditional wood siding, LP SmartPanel offers significant advantages. Traditional wood is susceptible to rot, insect infestation, and warping, requiring more frequent maintenance and replacement. LP SmartPanel’s engineered construction mitigates these issues, resulting in lower long-term costs. Compared to other competing products like vinyl or fiber cement siding, LP SmartPanel often offers a more natural wood look and feel, while maintaining superior durability and resistance to damage. Fiber cement can be brittle and prone to cracking, while vinyl can fade or become brittle over time. LP SmartPanel strikes a balance between natural aesthetics and lasting performance.

Price Comparison of LP SmartPanel with Other Building Materials

The cost of siding materials can vary depending on factors such as region, supplier, and project specifics. However, a general comparison of price points can be helpful in understanding the relative value proposition of LP SmartPanel. The following table provides estimated price ranges per square foot (these are estimates and may vary based on location and retailer):

| Material | Price Range per sq ft | Notes | Installation Cost (Estimate) |

|---|---|---|---|

| LP SmartPanel | $3.00 – $6.00 | Price varies based on profile and finish | $2.00 – $4.00 |

| Traditional Wood Siding | $2.00 – $5.00 | Significant variation based on wood type and quality | $2.50 – $5.00 |

| Vinyl Siding | $1.50 – $4.00 | Less expensive upfront but may require more frequent replacement | $1.00 – $3.00 |

| Fiber Cement Siding | $4.00 – $8.00 | High durability but more expensive than other options | $3.00 – $6.00 |

Applications of LP SmartPanel: Lp Smart Panel

LP SmartPanel, with its inherent strength, durability, and resistance to moisture, finds extensive use across a broad spectrum of construction projects. Its versatility allows for diverse applications, from residential siding and roofing to commercial structures and agricultural buildings. This section will delve into specific examples, showcasing the adaptability and performance of LP SmartPanel in various settings and climates.

Residential Applications of LP SmartPanel

LP SmartPanel is a popular choice for homeowners seeking a low-maintenance, aesthetically pleasing, and long-lasting exterior cladding solution. Its engineered wood construction provides superior strength and dimensional stability compared to traditional wood siding, minimizing warping, shrinking, and swelling. This translates to a more attractive and durable home exterior that requires less upkeep over time. Common residential applications include: siding for houses, garages, and outbuildings; fascia and soffit applications; and even accent pieces for enhanced visual appeal. For example, a craftsman-style home might use LP SmartPanel vertical siding to accentuate its distinct architectural features, while a modern farmhouse could incorporate LP SmartPanel in a horizontal configuration for a clean, contemporary look. The versatility of the product allows for creative design choices that enhance the overall curb appeal of a home.

Commercial Applications of LP SmartPanel

The robust nature of LP SmartPanel extends its utility beyond residential projects into the commercial construction sector. Its resistance to moisture damage, insect infestation, and decay makes it a cost-effective and reliable choice for various commercial structures. Case studies demonstrate its successful implementation in projects ranging from multi-family dwellings and retail spaces to agricultural buildings and industrial facilities. For instance, a large apartment complex might use LP SmartPanel for its exterior walls, benefiting from the material’s durability and resistance to the elements. Similarly, a commercial building in a coastal area would appreciate the panel’s resistance to moisture and salt spray, ensuring long-term structural integrity. The consistent quality and performance of LP SmartPanel contribute to the longevity and value of commercial buildings.

LP SmartPanel’s Suitability for Diverse Climates

The inherent design and manufacturing process of LP SmartPanel contributes to its suitability for a wide range of climates and weather conditions. The engineered wood construction, coupled with the proprietary treatment process, provides exceptional resistance to moisture, rot, and insect damage. This makes it a reliable choice for both humid, coastal regions and dry, arid environments. In areas with extreme temperature fluctuations, the dimensional stability of LP SmartPanel helps to minimize expansion and contraction, preventing warping and cracking. Furthermore, its resistance to fungal growth makes it suitable for regions with high humidity and rainfall. This durability across varied climates translates into lower maintenance costs and a longer lifespan for structures using LP SmartPanel.

Hypothetical House Design Utilizing LP SmartPanel

Imagine a two-story modern farmhouse situated on a gently sloping lot. The exterior cladding would primarily feature LP SmartPanel in a warm gray tone, creating a visually appealing contrast against the dark-colored windows and roof. The horizontal application of the LP SmartPanel siding would emphasize the home’s horizontal lines and create a sense of spaciousness. LP SmartPanel would also be used for the fascia and soffits, maintaining a cohesive aesthetic. A covered porch, featuring LP SmartPanel decking, would provide a welcoming entryway. This design demonstrates the versatility of LP SmartPanel, allowing for a visually stunning and durable home that can withstand various weather conditions, requiring minimal maintenance over its lifespan. The design prioritizes clean lines, natural light, and a harmonious blend of modern and traditional architectural elements, showcasing the aesthetic potential of LP SmartPanel.

Technical Specifications and Properties

LP SmartPanel’s superior performance stems from its unique engineering and manufacturing process. Understanding its technical specifications and properties is crucial for architects, builders, and homeowners alike, ensuring the right application and maximizing its lifespan and benefits. This section details the key characteristics that contribute to LP SmartPanel’s exceptional durability and dimensional stability.

Dimensional Stability of LP SmartPanel, Lp smart panel

LP SmartPanel exhibits excellent dimensional stability, meaning it resists warping, shrinking, and swelling under varying moisture conditions. This stability is achieved through the engineered wood strand technology and the proprietary treatment process. The strands are oriented and bonded in a way that minimizes the impact of moisture fluctuations. This results in a product that maintains its shape and size, even in climates with significant seasonal temperature and humidity changes. This consistent dimensional stability translates to a more predictable and easier installation process, reducing the likelihood of callbacks and project delays. For example, in regions with high humidity, LP SmartPanel is less likely to cup or warp compared to untreated wood, ensuring the structural integrity of the finished project.

Moisture Resistance and Durability of LP SmartPanel

The inherent moisture resistance of LP SmartPanel is a key differentiator. The wood strands are treated with a proprietary blend of waxes and resins, providing superior protection against water absorption. This significantly reduces the risk of rot, decay, and fungal growth, extending the panel’s lifespan considerably. Further enhancing durability, the SmartGuard® process protects the panel from insect infestation and provides additional resistance to harsh weather conditions. The combination of these factors results in a product that can withstand prolonged exposure to moisture and extreme weather, making it suitable for a wide range of exterior applications. For instance, siding constructed with LP SmartPanel can maintain its appearance and structural integrity for decades, even in coastal environments prone to salt spray and heavy rainfall.

Environmental Impact of LP SmartPanel Production and Disposal

LP SmartPanel’s environmental impact is a critical consideration. The manufacturing process utilizes sustainably sourced wood from responsibly managed forests, contributing to forest stewardship. While the manufacturing process does involve energy consumption and the generation of waste, LP Building Products actively works to minimize these impacts through continuous improvement initiatives. Recycling programs are also in place to help divert waste from landfills. Furthermore, the extended lifespan of LP SmartPanel reduces the need for frequent replacements, ultimately minimizing the long-term environmental impact compared to materials with shorter lifespans requiring more frequent replacement. Specific environmental certifications and impact data can be found on the LP Building Products website.

Technical Specifications of LP SmartPanel

The following table provides a concise overview of the technical specifications. Note that specific values may vary depending on the panel type and thickness.

| Property | Value | Property | Value |

|---|---|---|---|

| Thickness | Varies (e.g., 5/16″, 7/16″, ½”) | Width | 4′ x 8′ (standard) |

| Length | Varies (depending on panel type) | Surface Finish | Smooth, textured options available |

| Moisture Resistance | High, due to SmartGuard® treatment | Dimensional Stability | Excellent, resists warping and swelling |

| Fire Resistance | Meets or exceeds building codes | Warranty | Consult LP Building Products for details |

Installation and Maintenance

Proper installation and ongoing maintenance are crucial for maximizing the lifespan and performance of LP SmartPanel siding. Following best practices ensures a beautiful, durable, and long-lasting exterior for your building. This section details the installation process, maintenance recommendations, and solutions to common installation challenges.

LP SmartPanel Installation Steps

This section provides a step-by-step guide to installing LP SmartPanel siding, ensuring a professional and lasting result. Careful preparation and adherence to these steps are vital for a successful installation.

- Preparation: Begin by ensuring the underlying structure is properly prepared. This includes checking for any rot, damage, or warping to the sheathing. Any necessary repairs should be completed before installation begins. The surface should be clean, dry, and level. Establish a consistent and straight nailing line for the first course of siding.

- Installation of Starter Strip: Install a starter strip at the bottom of the wall, ensuring it is level and plumb. This provides a consistent base for the first row of panels and maintains a uniform look.

- First Panel Installation: Position the first LP SmartPanel against the starter strip, ensuring proper alignment. Nail the panel securely according to the manufacturer’s specifications, paying close attention to nail placement to avoid splitting the panel. Use galvanized nails of the appropriate size and length.

- Subsequent Panel Installation: Install subsequent panels, overlapping them according to the manufacturer’s recommendations. Maintain consistent spacing and alignment throughout the installation. Ensure proper nailing to prevent gaps or movement.

- Corner and Trim Installation: Install corner and trim pieces as needed, following the manufacturer’s guidelines. These pieces ensure a professional finish and protect the edges of the siding.

- Finishing Touches: After completing the siding installation, inspect the entire area for any gaps or imperfections. Address any issues immediately to maintain the integrity of the installation. Caulk any gaps as necessary.

LP SmartPanel Maintenance Best Practices

Regular maintenance will extend the life and beauty of your LP SmartPanel siding. These practices will help preserve its appearance and performance over time.

- Regular Cleaning: Clean the siding periodically with a soft brush and mild detergent to remove dirt, debris, and cobwebs. Avoid harsh chemicals or pressure washing, which can damage the surface.

- Prompt Repair of Damage: Address any damage, such as dents or scratches, promptly. Minor scratches can often be touched up with paint, while more significant damage may require panel replacement.

- Inspection for Pests: Periodically inspect the siding for signs of insect infestation. Address any infestations immediately to prevent further damage.

- Protection from Extreme Weather: Take steps to protect the siding from extreme weather conditions, such as heavy snow or ice accumulation. Regularly clear any snow or ice buildup to prevent damage.

Common Installation Challenges and Solutions

This section addresses common issues encountered during LP SmartPanel installation and provides practical solutions.

| Challenge | Solution |

|---|---|

| Panel warping or bowing | Ensure proper acclimation of the panels before installation. Check for underlying structural issues. |

| Nail pops | Use the correct type and size of nails. Ensure proper nailing technique and depth. |

| Gaps between panels | Check for proper panel alignment and overlap. Ensure consistent nailing. |

| Difficulty cutting panels | Use a sharp blade and appropriate cutting tools. Score the panel before cutting to prevent chipping. |

Visual Representation of Proper LP SmartPanel Installation

The illustration depicts a section of a wall with properly installed LP SmartPanel siding. The bottom shows a level starter strip. The first panel is installed, overlapping the starter strip and secured with appropriately spaced galvanized nails. Subsequent panels are shown overlapping the previous panels, maintaining a consistent vertical alignment and horizontal overlap. Corner trim pieces are shown neatly installed at the exterior corners, providing a clean and finished appearance. The nails are countersunk and painted to match the siding color. The overall appearance is consistent, straight, and free from gaps or visible nail heads. The illustration clearly shows the proper overlap and nailing techniques, highlighting the importance of precise installation for a professional and durable finish.

Sustainability and Environmental Impact

LP SmartPanel’s commitment to sustainability extends throughout its lifecycle, from responsible sourcing of raw materials to the potential for end-of-life recycling. The company actively works to minimize its environmental footprint, contributing to a greener building industry. This section details the various aspects of LP SmartPanel’s sustainable practices and their impact on the environment.

Sustainable forestry practices are fundamental to LP SmartPanel’s production. The company sources its wood from sustainably managed forests, certified by organizations like the Sustainable Forestry Initiative (SFI) and the Forest Stewardship Council (FSC). This ensures that the wood used comes from responsibly harvested sources, promoting forest health and biodiversity. These certifications guarantee that logging operations adhere to strict environmental standards, minimizing habitat disruption and promoting reforestation efforts. LP actively participates in reforestation programs, further contributing to the long-term health of forest ecosystems.

Recycled Content and Recycling Potential

LP SmartPanel incorporates recycled content in its manufacturing process, although the precise percentage may vary depending on the specific product line and availability of recycled materials. The company continuously explores ways to increase the use of recycled materials in its production, aligning with broader industry trends toward circular economy principles. While LP SmartPanel itself is not currently widely recycled in the same manner as some other materials, research and development efforts are ongoing to explore and improve end-of-life management options, including potential for future recycling or repurposing of the material. The durability and longevity of the panel contribute to its reduced overall environmental impact, even without direct recycling at present.

Carbon Footprint Comparison

Assessing the carbon footprint of building materials requires a comprehensive life-cycle assessment (LCA). While precise figures vary depending on the specific manufacturing processes, transportation distances, and other factors, studies generally indicate that wood-based products like LP SmartPanel often have a lower carbon footprint compared to some other common building materials, such as concrete or steel. This is primarily due to the carbon sequestration capabilities of wood during its growth phase. Trees absorb carbon dioxide from the atmosphere during their lifecycle, effectively storing carbon. The use of sustainably sourced wood, as in the case of LP SmartPanel, further reduces the overall environmental impact by minimizing deforestation and promoting forest health. For instance, a comparison of LCAs for various building materials, published by reputable organizations, might show a significant reduction in greenhouse gas emissions when choosing LP SmartPanel over steel or concrete in certain applications.

Long-Term Environmental Benefits

The long-term environmental benefits of using LP SmartPanel extend beyond its lower carbon footprint. The durability and resistance to rot, insects, and moisture contribute to a longer lifespan for structures, reducing the need for frequent replacements and associated material consumption and waste generation. This longevity minimizes the overall environmental impact over the building’s entire lifecycle. Furthermore, the use of LP SmartPanel can contribute to energy efficiency in buildings. Its insulating properties can help reduce heating and cooling energy demands, leading to lower energy consumption and decreased greenhouse gas emissions over the building’s operational lifespan. This translates to long-term environmental benefits and contributes to a more sustainable built environment.

Warranty and Customer Support

LP Building Products stands behind the quality of its LP SmartPanel engineered wood siding with a comprehensive warranty designed to protect homeowners and builders. Understanding the warranty details and available support resources is crucial for maximizing the lifespan and performance of your LP SmartPanel investment. This section Artikels the warranty provisions and the various customer support options provided by LP Building Products.

LP SmartPanel siding carries a limited warranty that varies depending on the specific product and its intended application. It’s essential to consult the warranty certificate included with your purchase for complete details as coverage specifics may change over time. Generally, the warranty covers defects in manufacturing and materials, protecting against issues such as delamination, cracking, and surface damage under normal use and installation. However, exclusions typically include damage resulting from improper installation, acts of nature, or normal wear and tear.

Warranty Coverage Details

The LP SmartPanel warranty typically covers the product for a specified period against manufacturing defects. This timeframe often differs depending on the specific product and application. For example, the warranty for residential applications might differ from that for commercial projects. The warranty often includes provisions for repair or replacement of defective panels, subject to the verification of the claim by LP Building Products. The warranty does not usually cover labor costs associated with repair or replacement.

Customer Support Resources

LP Building Products offers multiple avenues for customers to access support and assistance. These resources are designed to help customers resolve issues, troubleshoot problems, and ensure they receive the maximum benefit from their LP SmartPanel investment. Proactive engagement with these resources can significantly improve the overall customer experience.

- Website: The LP Building Products website provides comprehensive information on their products, including detailed warranty information, FAQs, installation guides, and troubleshooting tips. The website also offers a contact form for submitting inquiries.

- Phone Support: A dedicated customer service phone line allows direct communication with LP Building Products representatives. Trained professionals can answer questions, provide technical assistance, and guide customers through the warranty claim process.

- Email Support: Customers can also contact LP Building Products via email for inquiries and support requests. This option provides a written record of the communication and is suitable for more detailed or complex issues.

- Dealer Network: LP Building Products works with a network of authorized dealers who can provide installation support, answer questions, and assist with warranty claims. Contacting a local dealer may be the quickest and most convenient way to resolve issues.

Examples of Successful Customer Service Interactions

While specific customer interactions are confidential, LP Building Products frequently receives positive feedback regarding its responsiveness and helpfulness. Many customers report successful resolutions to issues related to installation problems, damaged panels, and warranty claims. The company’s commitment to customer satisfaction is evident in its proactive approach to resolving problems and ensuring customer confidence in their products. For instance, a customer reporting a manufacturing defect might receive prompt replacement panels, minimizing disruption to their project.

Warranty Claims and Troubleshooting

Filing a warranty claim and troubleshooting potential issues with LP SmartPanel requires a systematic approach. Following these steps can streamline the process and ensure a timely resolution.

- Document the Problem: Take detailed photographs or videos of the damaged panels, noting the location, extent of the damage, and any relevant circumstances.

- Review the Warranty: Carefully review your warranty certificate to understand the coverage, exclusions, and claim procedures.

- Contact LP Building Products: Contact LP Building Products through your preferred method (phone, email, or website) to initiate a warranty claim. Provide all necessary information, including purchase date, product details, and supporting documentation.

- Follow Instructions: Follow the instructions provided by LP Building Products regarding the claim process. This may include submitting additional documentation or photographs.

- Troubleshooting Common Issues: Before filing a claim, consider troubleshooting common issues such as improper installation or environmental damage. LP Building Products’ website and resources often provide guidance on addressing these problems.

LP SmartPanel stands out as a robust and eco-conscious choice for exterior cladding, combining superior performance with sustainable practices. Its inherent durability, resistance to the elements, and ease of installation make it a compelling option for a wide range of projects. By understanding its technical specifications, environmental impact, and the support offered by LP Building Products, you can confidently make informed decisions regarding its use in your next construction undertaking. The long-term value and reduced maintenance associated with LP SmartPanel solidify its position as a leading material in the building industry.

FAQ Compilation

What is the lifespan of LP SmartPanel?

LP SmartPanel is designed for long-term durability, with a lifespan comparable to, or exceeding, that of traditional wood siding, depending on climate and maintenance.

Can LP SmartPanel be painted?

Yes, LP SmartPanel can be painted with appropriate exterior-grade paints and primers. Proper surface preparation is key for optimal adhesion and longevity.

Is LP SmartPanel fire-resistant?

While LP SmartPanel is treated for moisture and insect resistance, it is not inherently fire-resistant. However, it can be treated with fire-retardant products for enhanced fire safety.

How does LP SmartPanel compare in terms of cost to vinyl siding?

The cost of LP SmartPanel generally falls between that of traditional wood and high-end vinyl siding. The long-term durability and reduced maintenance can offset the initial cost difference.

Where can I find an LP SmartPanel installer near me?

LP Building Products’ website typically offers a dealer locator tool to help you find certified installers in your area.